All-Day Protection.

All-Day Protection.

WELCOME TO PROKHAR PPF

Guard the Gloss. Keep the Story. PROKHAR car paint protection film (car PPF / car clear bra) is a high-performance, aliphatic TPU cast film engineered to keep vehicle paint looking showroom-fresh while making installation, resale and aftercare simpler for professional shops and trade partners.

What Is Car Paint Protection Film?

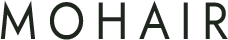

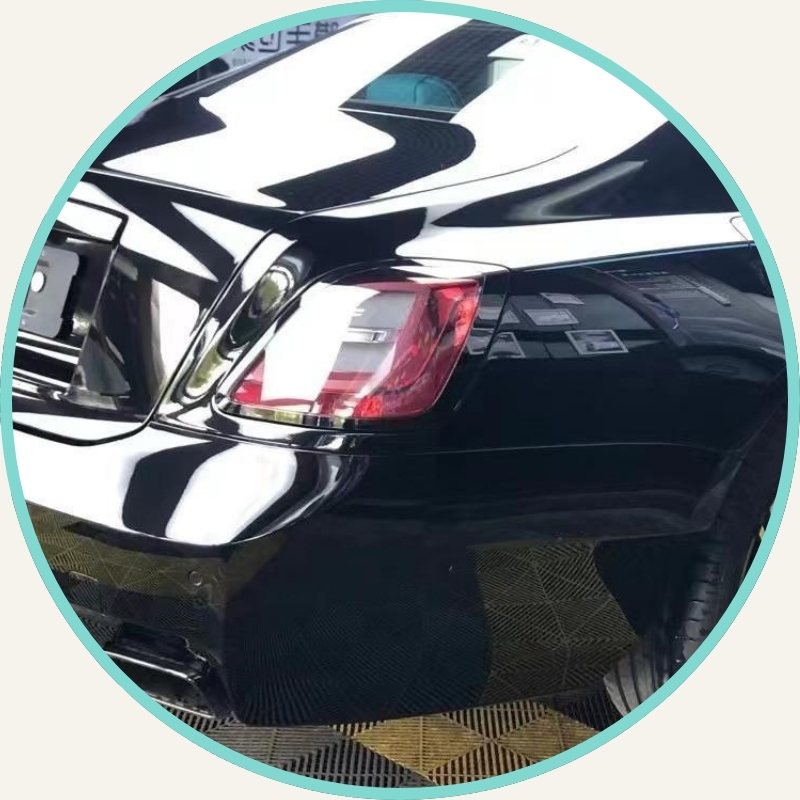

A car paint protection film is a transparent, sacrificial film applied to painted surfaces to guard against road debris, stone chips, bird droppings, tree sap, insect residue and light abrasions. PROKHAR PPF uses aliphatic TPU as its backbone—delivering long-term clarity, low yellowing and superior mechanical resilience compared with older TPH or PVC solutions.

Why PROKHAR PPF

- Aliphatic TPU core — selected raw materials and an eco-aware formulation reduce chemical interaction with paint while offering exceptional elasticity and tensile strength.

- Cast-film precision — advanced casting and Davis-standard style handling produce uniform thickness, minimal shrinkage and consistent adhesion across batches.

- High gloss + self-healing — industry-grade surface coatings restore light scratches with heat and maintain a deep, wet-look finish.

- UV & yellowing resistance — formulated to stay clear in harsh climates and retain optical clarity longer than conventional films.

- Low-viscosity, repositionable adhesive — speeds templating and fitment for detailers; allows fine-tuning during install without residue.

- Tough & flexible — excellent puncture and tear resistance while conforming to curves, bumpers and complex panels.

- Trade-ready supply chain — end-to-end quality control by Parfait Decoration International ensures stable lead times, batch traceability and scalable production for distributors and wholesalers.

Business Benefits For Shops, Distributors And Traders

Auto detailing shops / vehicle PPF installers

- Faster installs with easy repositioning and low shrink; finishes that reduce re-work.

- Reliable surface behavior for precision edges, seams and complex geometry.

- Fewer callbacks thanks to self-healing and long-term clarity.

Distributors & wholesalers

- Stable, standardized SKUs and packaging for smooth inventory management.

- Consistent lot quality and testable specs reduce QC overhead.

- Flexible MOQ and logistics support for different territories.

Traders & resellers

- High perceived value product (performance + premium branding) that supports healthy margins.

- Co-op marketing assets to help close sales.

Vs. Ceramic Coating

- What PPF (car clear bra) does best: PPF is a physical, sacrificial shield that absorbs impact energy from road debris, stone chips and small abrasions. It provides immediate, mechanical protection on high-risk zones (hood, bumper, mirrors) and is removable for repair or resale. For protection against stones and physical damage, no liquid coating matches the barrier of a full-film system.

- What ceramic coating does best: Ceramic coatings are liquid polymers that chemically bond to paint, improving hydrophobicity, chemical resistance and long-term gloss. They make maintenance easier and help resist staining, but they do not stop rock chips or heavy mechanical impacts.

- Why many pros pair them: The highest-value packages combine PROKHAR PPF on high-impact areas with a ceramic coating on exposed painted surfaces (or a spray ceramic over film) — giving impact protection where it matters and easier maintenance + enhanced gloss elsewhere. This hybrid approach maximizes lifetime protection and resale value.

Front Fender

Hood

Front Bumper

Door

Side Mirror Housing

Side Skirts

Roof

Trunk Lid

Rear Fender

Rear Bumper

PROKHAR PPF — Not Just Film, Peace of Mind

Protect the factory finish with a purpose-built film. PROKHAR PPF is a cast, aliphatic TPU paint protection system engineered for professional installers, distributors and trade partners who demand reliable optics, durability and predictable installation performance across global climates.

KEY FEATURES & ADVANTAGES

- Aliphatic TPU backbone — PROKHAR selects premium TPU as the structural core for superior elasticity, tensile strength and long-term optical clarity. This material choice reduces yellowing and helps the film retain a showroom finish for years.

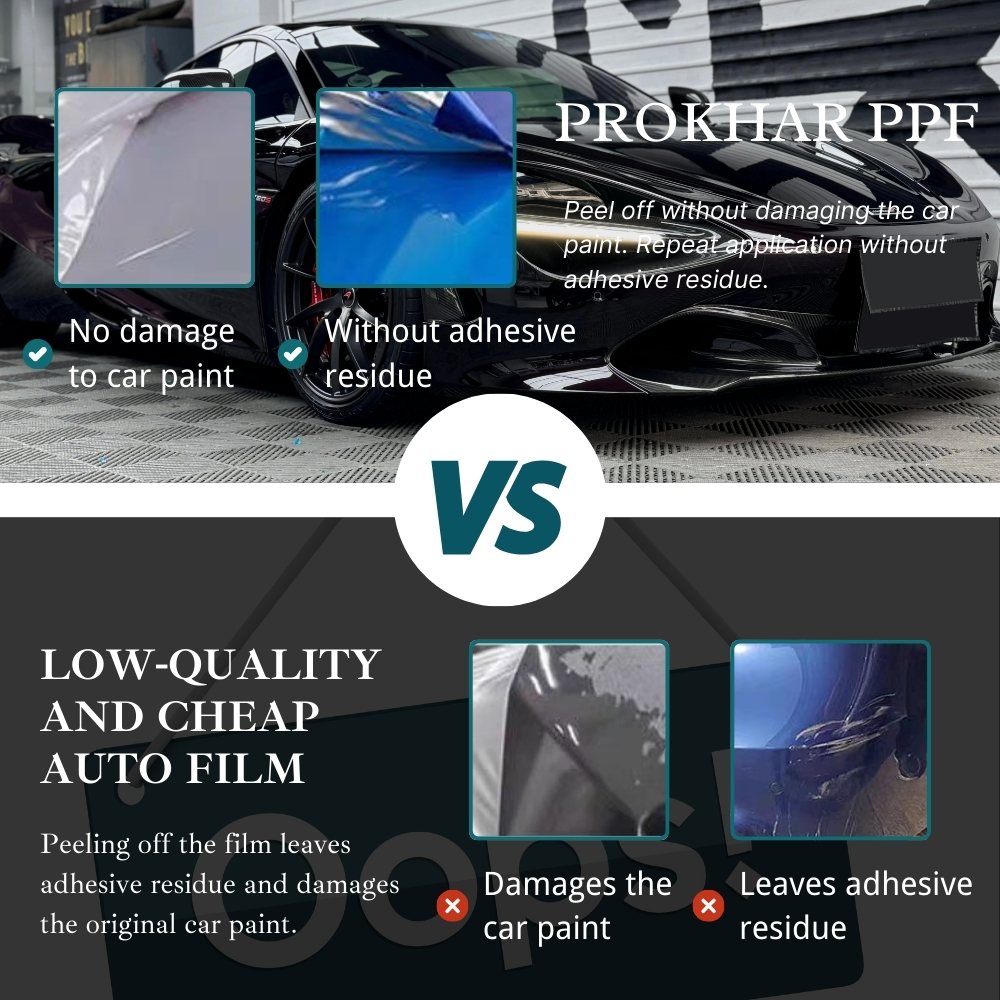

- Carefully matched topcoat & adhesive — We pair advanced, weather-resistant topcoats (customized supply options) with low-viscosity, repositionable adhesives that allow fast templating, fine edge work and clean removability. Industry-grade adhesive systems (used widely across high-end PPF products) deliver strong adhesion in service yet remove without damaging OEM paint when applied/removed correctly.

- End-to-end quality control — From selected TPU pellets through coating and casting, PROKHAR enforces factory traceability and standardized production lines so distributors and wholesalers receive consistent lot quality and predictable performance.

- Precision cast manufacturing — Advanced casting and production controls minimize thickness variance and shrinkage, improving fitment and reducing install rework.

- High gloss + self-healing — Heat or ambient self-healing topcoats recover light swirl marks and fine scratches, preserving gloss and lowering callbacks for installers.

- UV & anti-yellow formulation — Optimized aliphatic chemistry and protective coatings keep clarity in sun-intensive markets and extend usable life vs older PVC/TPH constructions.

- Low shrink / easy install behavior — Minimal dimensional change after installation keeps seams tight, edges clean and reduces the need for post-heat corrective work.

- Removable without paint damage — When correctly specified and installed, PROKHAR PPF acts as a sacrificial layer and can be removed cleanly, leaving the factory paint intact.

- Trade friendly — Standardized SKUs, packaging for retail/distribution, technical documentation make onboarding and inventory management simple for partners.

Self-Healing & Mirror-Gloss

Nano-Hydrophobic Surface

UV-Stable, Anti-Yellow Formulation

Rock-Chip & Impact Defense

Installer-Friendly Fit & Low Shrinkage

Trade-Grade Consistency & Support

Mud and dirt

Wind and sand splash

Acid rain corrosion

Animal faecal residues

Accidental scratching

Oxidised ageing

Malicious scratching

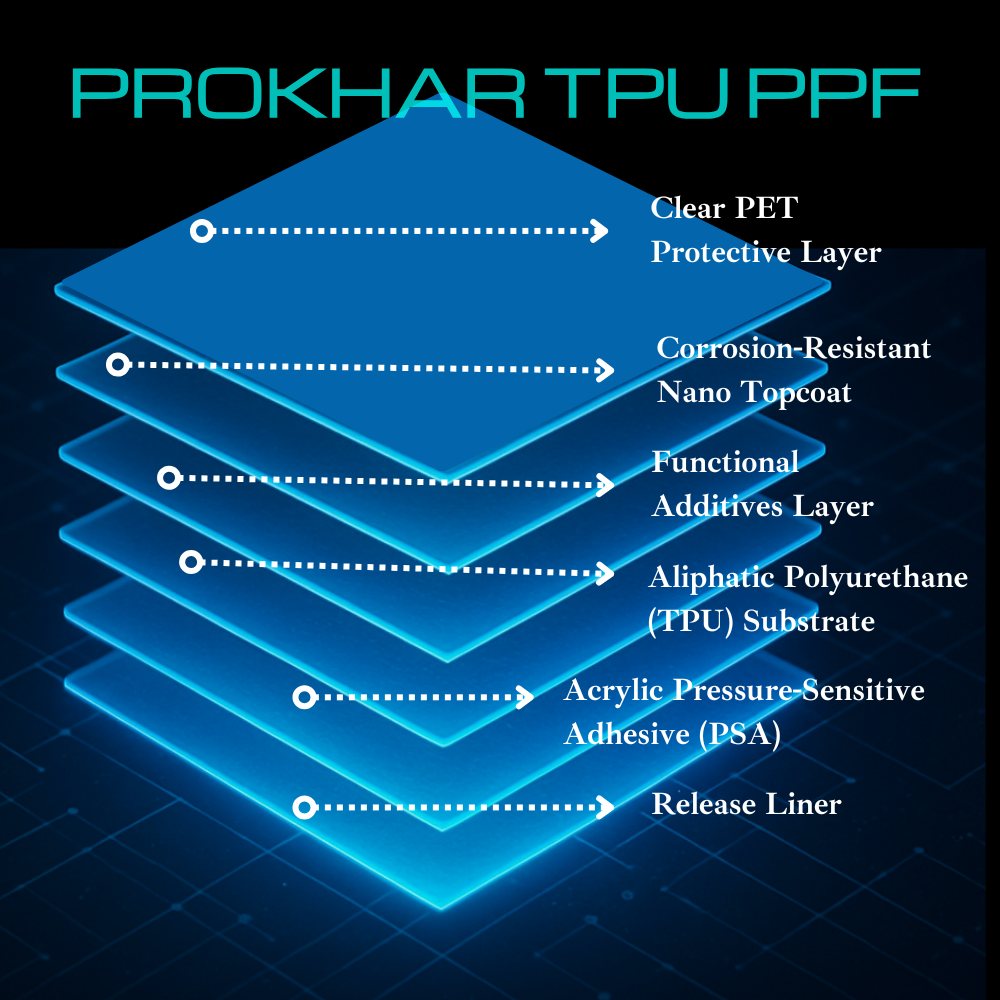

Product Structure

PROKHAR Car PPF

Clear PET Protective Layer (Top removable guard during manufacture & transport)

- Thin transparent PET film applied as a temporary protective barrier.

- Shields the underlying functional topcoat during cutting, roll handling and shipping; prevents micro-abrasions and contamination before final installation.

Topcoat — Corrosion-Resistant Nano Topcoat + Self-Healing Coating

- High-performance nano topcoat manufactured in Japan, enhanced with ceramic nanoparticles and a self-healing polymer matrix.

- Provides hydrophobic/oleophobic surface properties, superior resistance to acids/alkalis/salts, surface scratch resistance and thermal self-healing for light abrasions when heat-activated.

- Ceramic nano-fillers increase stain resistance and long-term gloss retention — a key selling point for premium car clear bra customers.

Functional Additives Layer

- Nanocoatings and high-gloss treatments integrated into or atop the topcoat.

- Boosts initial and long-term gloss, improves surface smoothness for easier cleaning and better visual depth.

- Enhanced showroom finish that helps installers demonstrate value to end customers.

Aliphatic Polyurethane (TPU) Substrate — Core Protective Layer

- High-grade aliphatic TPU formulated for low yellowing, high elongation and impact energy absorption.

- Primary protective body of the film — provides elasticity for complex curves, impact resistance against stone chips, tear resistance and optical transparency.

- Aliphatic chemistry offers superior UV/yellowing stability versus aromatic TPUs, ensuring clarity and color-fast performance over years.

Acrylic Pressure-Sensitive Adhesive (PSA)

- High-performance acrylic adhesive supplied to PROKHAR spec (Ashland/Henkel grade).

- Secure, long-lasting bond to automotive paint while allowing repositioning during installation; engineered for low residue on removal and minimal paint interaction.

- Installer confidence through consistent tack, clean removability and reduced callbacks.

Release Liner (Backing for storage & cutting)

- Silicone-coated release liner that protects the PSA until application.

- Facilitates storage, precision cutting and transport; peeled away immediately before install.

- Stable, flat liners that reduce mis-cuts and speed pre-cut workflows for distributors and installers.

WARRANTY COVERAGE

Quality guarantee (applies by product category within the stated warranty period):

- Guarantee the film’s adhesion — no spontaneous deformation, delamination or natural detachment from the vehicle surface.

- Guarantee the film’s appearance — no obvious fading from sunlight.

- Guarantee clean removal — the film will leave virtually no adhesive residue and will not cause original factory paint to flake or peel (damage to areas that have been repainted is excluded).

PROKHAR PPF official warranty: If any of the above issues occur, the affected film will be replaced.

DAILY CARE AND MAINTENANCE INSTRUCTIONS:

A. First 7 days — critical ‘settling’ window

Wait 48–72 hours before any washing or waxing to allow adhesive to set; many brands recommend avoiding high-pressure washes and automatic tunnels for up to 7 days. For PROKHAR installs we advise avoiding high-speed highway driving and high-pressure car-wash nozzles for the first 5–7 days.

B. Regular wash routine

Hand wash whenever possible using a pH-neutral car shampoo and the two-bucket method (one bucket for rinse, one for soap). Avoid abrasive sponges or brushes; use soft microfiber mitts/towels.

Rinse thoroughly and dry with a clean microfiber towel or blower to avoid mineral spots. Avoid prolonged air-drying when water hardness is high.

C. Avoid aggressive machines & high-pressure at edges

Do not subject film edges to concentrated high-pressure nozzles; directed high-pressure washes can cause localized lifting if done too soon after install or repeatedly at the seams. Where automated washes are unavoidable, select touchless, low-pressure options and avoid edge-focused jets.

D. Immediate spot care for corrosive contaminants

Clean bird droppings, insect residue, tree sap, tar or other acidic/abrasive contaminants as soon as possible. Soak the area with warm, soapy water to soften, then gently remove with a soft cloth — do not scrub aggressively. For stubborn stains, advise customers to visit an authorized PROKHAR dealer for professional treatment.

E. Sealants & coatings — optional, value-adding maintenance

Use only approved sealants or PPF-safe ceramic coatings. A light re-seal every ~3 months preserves hydrophobic performance and gloss on many high-gloss PPFs. Avoid traditional abrasive polishing or aggressive compounds on PPF.

F. Scheduled inspections & professional service

Recommend customers bring vehicles back for a 7-day post-install inspection (common trade practice) to confirm edge adhesion and overall fit. Advise quarterly visual checks / maintenance to remove contaminants before they bond to the surface. If bubbles or edge lift appear later, contact the installing PROKHAR dealer to assess and repair under warranty guidelines.

G. What not to do

Don’t use abrasive pads, scrapers, or harsh solvent cleaners at property owner level.

Don’t fold or aggressively peel film during removal — authorized dealers should perform removals.

Price Tiers & Specialty Line

Luxury tier — CelestFlux Series

Default: 7.5 mil (custom thicker options available)

Core: premium TPU sourced for top optical performance (Lubrizol ESTANE® class) combined with customized Japanese topcoat and high-grade adhesives. Designed for flagship dealers and high-end chains competing with international premium brands. Exceptional tensile strength, tear resistance, highest anti-yellowing performance, maximum gloss and stain resistance. Packaged for luxury distribution.

Premium tier — PulseLuxe Series

Default: 7.5 mil (also available in 8.5 mil and 10 mil)

Options: heat-activated and instant/self-healing topcoat variants; advanced nano-hydrophobic topcoat. High elongation, superior tensile strength and mirror gloss. Designed for whole-vehicle and windshield compatibility (transparent windshield-safe option), and for customers who want premium protection or extreme-environment versions.

Standard tier — StarLustre Series

Default: 7.5 mil (8.5 mil and 9.5 mil available)

Feature set: thicker clear top-coat for elevated protection, heat or room-temperature self-healing options. Positioned as the go-to, high-turnover SKU for busy detail shops and regional wholesalers.

Value tier — PrismSheen Series

Default: 7.5 mil (8.5 mil optional)

Balanced, cost-aware formulation with durable anti-scratch and anti-yellow coatings. Reliable performance for small chains and mid-volume buyers, with occasional promotional wholesale pricing to support partner growth.

Economy tier — MythicGuard Series

Default: 7.5 mil (8.5 mil optional)

Factory-direct cost optimization for price-sensitive distributors and small shops. No MOQ constraints to let emerging channels test and scale quickly.

Special tier — MoonVeil Series

Default: 7.5 mil; finishes: gloss black, matte black, matte clear

Aesthetic-focused PPF variants that extend the standard line for customers who want stealth or distinctive finishes while keeping protective performance and multi-layer defense.

CF-PK1

PL-PK1

PL-PK2-IH

PL-PK2-X

PL-PK2-E

SL-PK1

SL-PK2-IH

SL-PK3

SL-PK-X

SL-PK-E

PS-PK1-IH

PS-PK2

MG-PK1

MG-PK2

MG-PK3

MV-GB

MV-MB

MV-MC

Keep It Original, Keep It Perfect

Showroom Gloss With Rock-Chip Defense

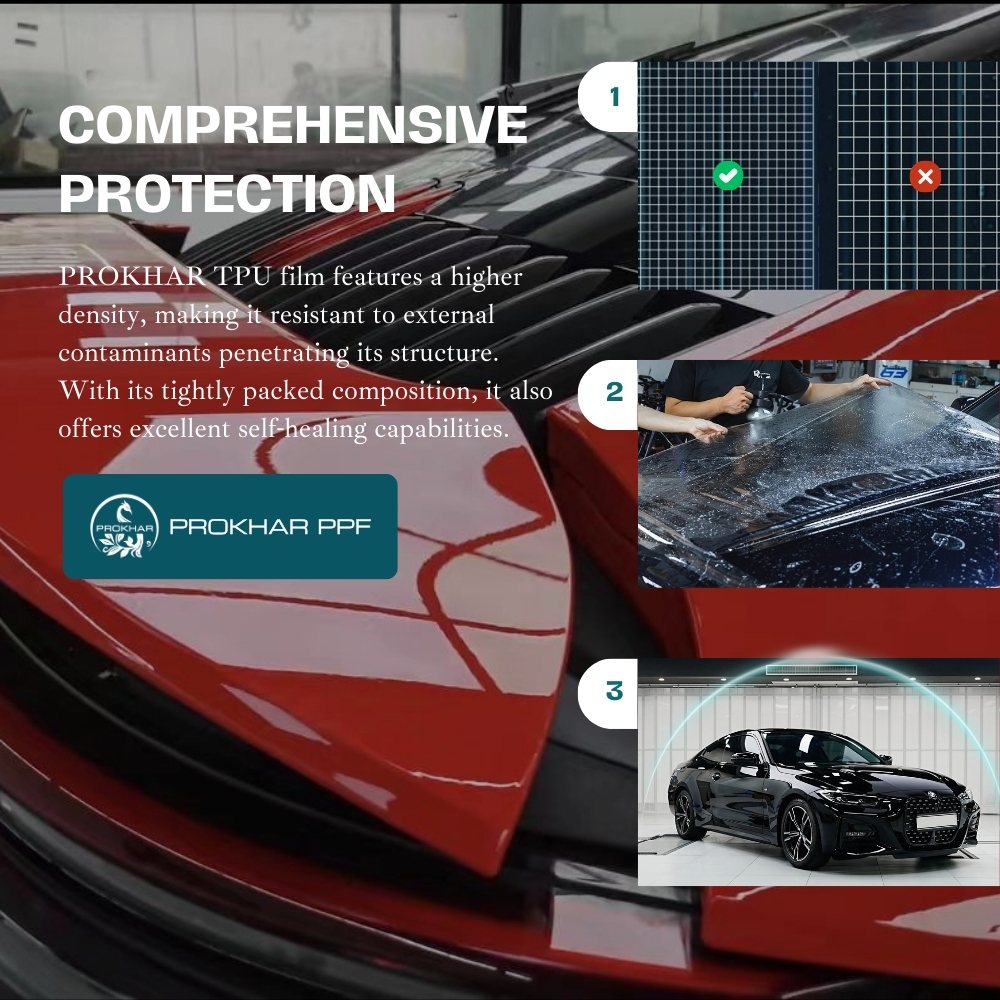

PROKHAR’s car paint protection film is engineered from high-density aliphatic TPU to form a crystal-clear, sacrificial shield that preserves the factory finish. A fifth-generation nano-hydrophobic topcoat makes water bead and roll off, carrying dirt and contaminants away so surfaces stay cleaner and streak-free. Built-in anti-yellowing chemistry keeps clarity over years — delivering roughly 40% more perceived gloss than factory paint and about 10% more sheen than standard PPF. Self-healing topcoats allow light scratches to vanish at room temperature, while the film’s robust tensile and tear properties absorb stone chips, insect acids, bird droppings, UV and acid rain — ideal for harsh roads and demanding climates. PROKHAR ppf gives vehicles a high-gloss, durable barrier that protects value and appearance.

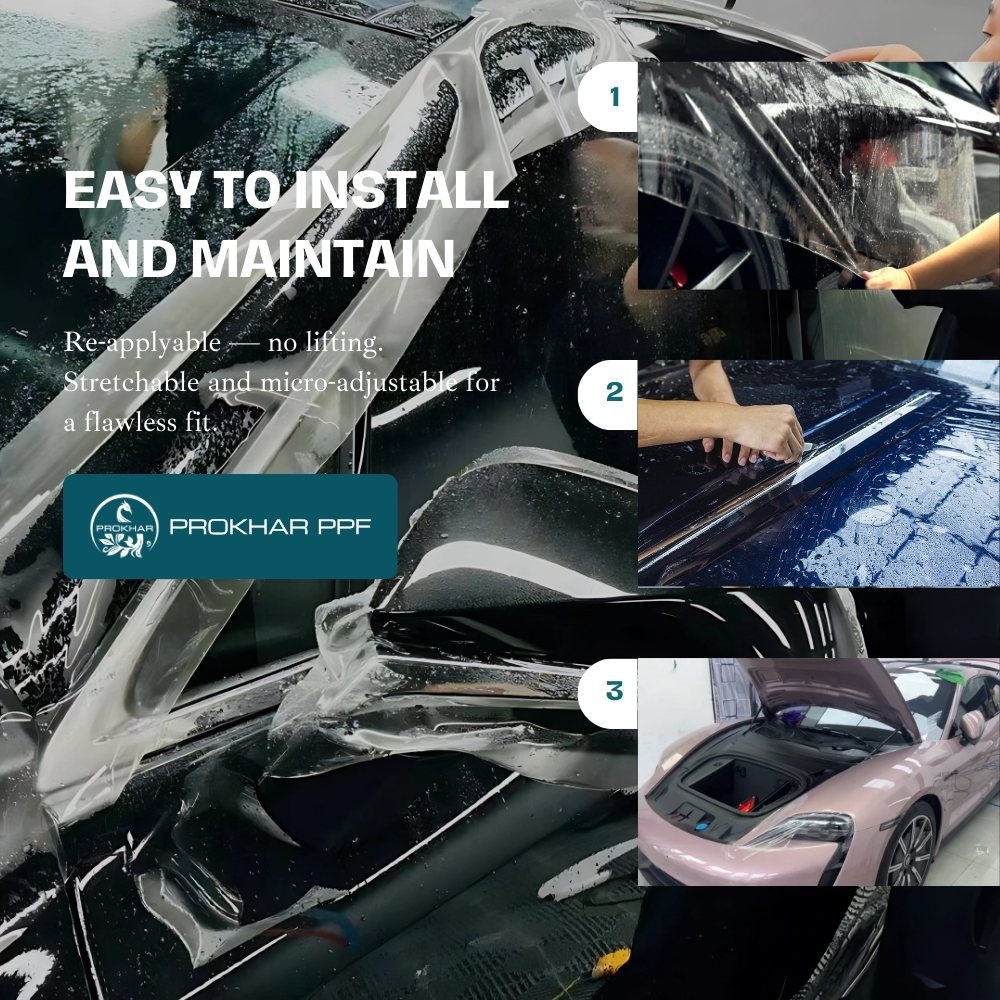

Designed For Pros And High-Volume Trade

From templating to finish, PROKHAR car ppf was developed to reduce install time and callbacks. Exceptional elasticity (over 250% elongation) and engineered flexibility let the film conform to complex curves and tight edges with minimal stretching or lifting. The adhesive system balances secure long-term hold with repositionability during fitment, and removes cleanly without residue or damage to OEM paint when following recommended procedures. Rated to withstand extremes (-40°C to 150°C) the film keeps shape and performance under severe heat or cold. Low shrinkage and consistent cast thickness cut material waste and make batch behavior predictable — a real advantage for detailers, distributors and traders managing inventory and installs. PROKHAR ppf simplifies installation, speeds throughput and lowers after-service work.

Bulk or single-job? We’ve got both.

Tell which PPF series and price tier you need — get a custom quote that suits your shop or distribution plan.