Tangible Peace Of Mind.

Tangible Peace Of Mind.

WELCOME TO PROKHAR TINT

Privacy, Performance, Peace. PROKHAR window film is a high-performance automotive glass protection system engineered for installers, distributors and fleet customers who demand measurable comfort, durability and appearance. Built from advanced multi-layer constructions and modern coating technologies, PROKHAR tinting delivers superior heat rejection, near-complete UV protection, low optical distortion, and preserved wireless/GPS connectivity — all while adding a refined, modern look to the vehicle. Our films are designed for fast, predictable installation and long-term stability, giving shops and resellers a reliable product to build warranties and repeat business around.

What is car window film?

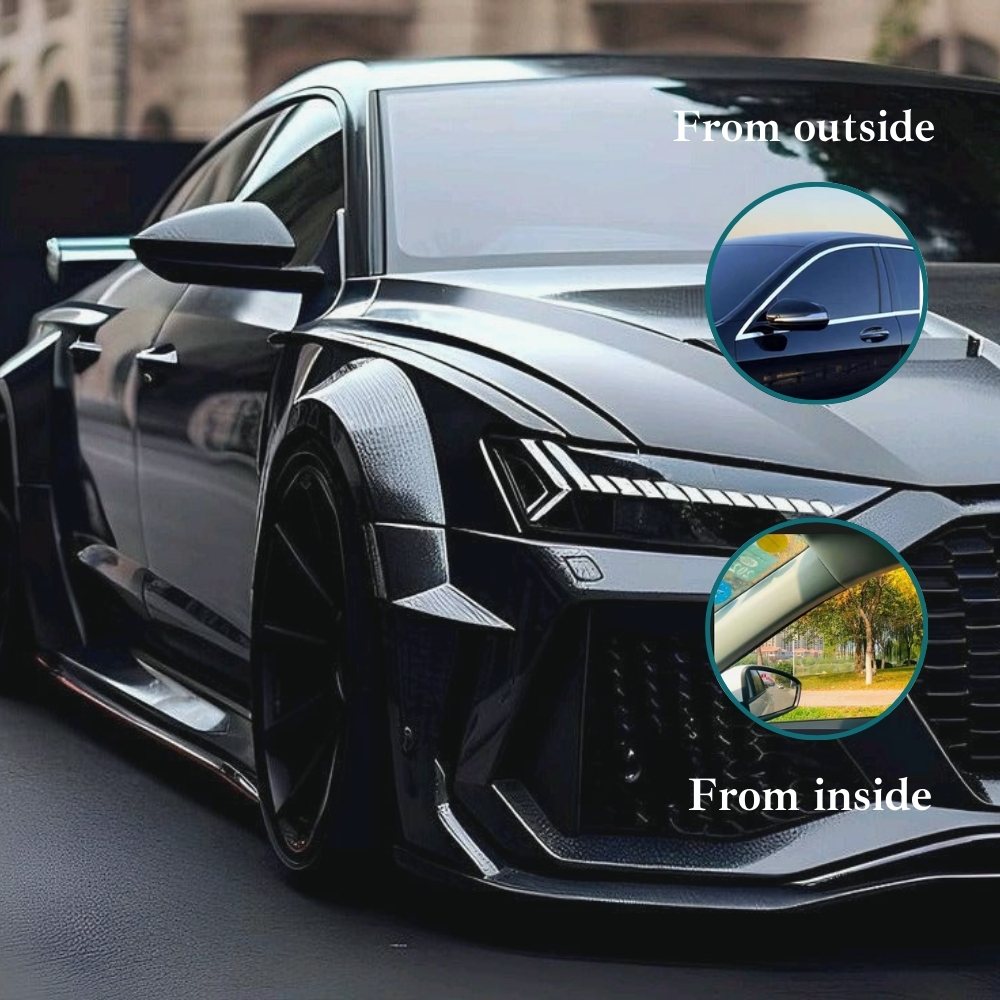

Car window film — commonly called car tint or solar film — is a thin engineered film applied to automotive glass to control heat, block ultraviolet radiation, reduce glare, increase privacy and add impact resistance. Modern films are multilayer laminates that combine polymer carriers, high-transmission adhesives, and performance coatings (ceramic, metal or optical layers). Besides comfort and style, quality automotive window film improves occupant protection by holding glass shards together on impact and helps preserve interiors by blocking fade. PROKHAR solar film is tuned to balance heat rejection, visible light transmission (VLT) and optical clarity so drivers get comfort without compromising signal reception or visibility.

What is nano-ceramic window film?

Nano-ceramic window film embeds microscopic ceramic (non-metallic) particles into the film’s coating. Those nano-scale ceramics strongly reject infrared (heat-generating) wavelengths while being optically clear in the visible range, so you keep natural light without the heat. Benefits include high IR and UV rejection, no metalization (so no signal interference), long color stability and very low haze for undistorted visibility. This is the technology installers choose when customers want best-in-class comfort with uninterrupted mobile/GPS/radio performance. PROKHAR’s ceramic range mirrors these advantages — engineered for strong IR/solar rejection, 99%+ UV protection and high optical clarity.

What is magnetron-sputtered (metal) window film?

Magnetron sputtering is a vacuum deposition process that applies ultra-thin metal or metal-oxide layers onto the film substrate. Sputtered films (often called metalized or sputtered metal films) can deliver excellent total heat rejection and distinctive metallic aesthetics. Modern sputtered products use precious metals and multi-layer stacks to control spectral behavior (heat vs visible light) while reducing the reflectivity and durability issues of older metal films. Advanced magnetron-sputtered lines on the market now match high heat rejection with stable color and improved corrosion resistance; PROKHAR’s sputtered options use the latest multi-layer sputtering processes to offer strong thermal performance with minimal signal impact and long-term durability.

What is titanium-nitride (TiN) film?

TiN sputtered vs TiN nano-ceramic

Titanium nitride (TiN) is a high-performance optical coating used two main ways:

• TiN magnetron-sputtered films — TiN is deposited as ultra-thin metal(-like) layers using sputtering. This produces excellent spectral control (very good IR rejection with specific visible transmission profiles) and a premium look.

• TiN nano-ceramic constructions — we combine TiN within a multi-layer, nano-ceramic stack to get the thermal benefits of TiN plus the non-metallic advantages (very low signal interference and high optical clarity) of ceramic technology.

Dual-layer TiN constructions to maximize heat rejection, durability and optical neutrality. PROKHAR offers TiN variants that take advantage of both approaches so customers can choose the aesthetic and performance tradeoff they prefer.

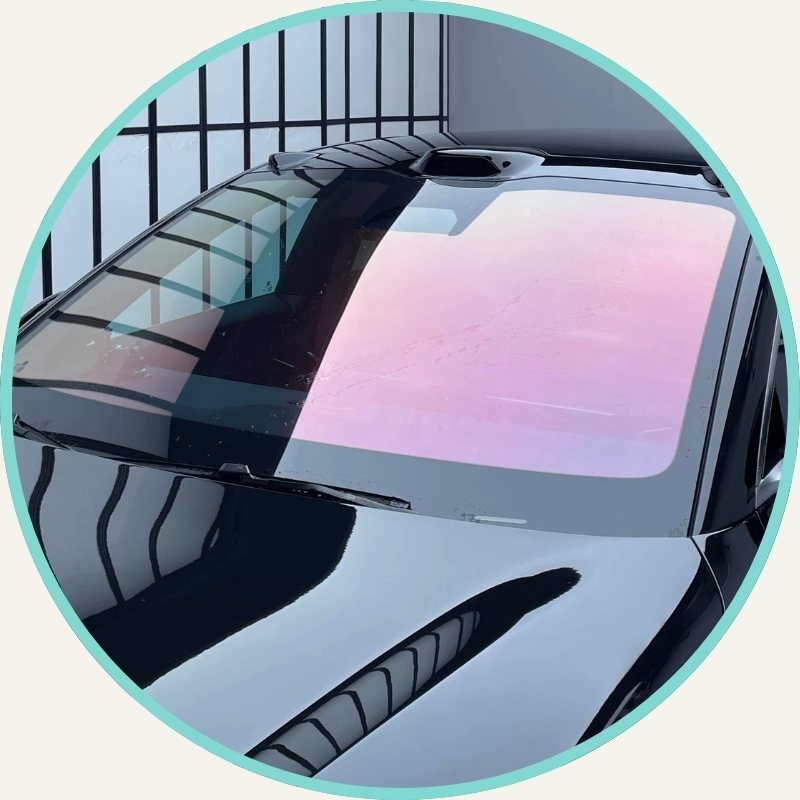

What are multi-layer spectrally-selective (colored / optical) films?

Multi-layer spectrally-selective films use dozens of thin polymer and coating layers to selectively reflect or transmit specific parts of the solar spectrum. Instead of relying on bulk metal, these optical stacks can be engineered to allow a lot of visible light while rejecting infrared — so the car feels cool but still bright. These films also enable subtle color effects (blue, green, bronze, etc.) and angle-dependent “spectral” or metallic appearances that shift slightly with viewing angle — a look many premium brands promote as “optical” or “spectrally-selective” styling. The advantage is attractive, modern aesthetics plus fine-tuned heat control and high clarity; PROKHAR’s optical series is manufactured with multi-layer coating techniques to achieve vibrant yet stable color, metallic texture and excellent solar performance.

Why PROKHAR Window Tint?

- Proven heat control: IR and total solar rejection engineered to keep cabin temps lower and reduce A/C load. (Configurations reach industry-leading IR/solar rejection levels.)

- 99% UV protection: Protects skin and prevents interior fading and material breakdown.

- Wide VLT range & aesthetics: Options from about 5% to 78% VLT, with neutral, colored and metallic looks to match OEM styling and local regulations.

- Safety laminate & impact control: Multi-layer adhesive and high-strength film hold glass fragments on impact, reducing shard scatter and improving occupant safety.

- Low haze, high clarity: Optical formulations keep visual distortion <0.5–2% for accurate, distortion-free sightlines.

- Signal-friendly choices: Ceramic and modern sputtered products preserve GPS, mobile and Bluetooth reception when specified.

- Durability & installation: Engineered for fast, predictable installation and long life in fleet and retail environments.

- Spectral & color technologies: Multi-layer optical coatings deliver angle-dependent color and premium metallic finishes without sacrificing clarity.

PROKHAR Tint — Drive Cool, Stay Secure

PROKHAR delivers a professional-grade line of car window film designed for automotive detail shops, distributors and trade partners who need measurable performance, easy installation and strong resale value. Combining titanium-nitride innovations, magnetron-sputtered metal layers and advanced nano-ceramic stacks, PROKHAR tinting balances extreme heat rejection, true optical clarity and day-to-day reliability — with the product breadth to match every market and climate.

KEY FEATURES & ADVANTAGES

- Best-in-class UV protection (≥99% UVR) to stop interior fading and protect occupants’ skin.

- High infrared rejection (IRR) and measurable total solar energy rejection (TSER) to lower cabin temperature and A/C load — selectable by series for fleet or boutique customers.

- Low optical haze (<0.15–2%) and high clarity so visibility and driver safety are preserved while delivering a premium look.

- Signal-friendly options — ceramic and modern multi-layer optical films are non-metallic or engineered to avoid mobile/GPS/RF disruption.

- Safety laminates & impact control — multi-layer adhesive constructions reduce shard scatter on glass breakage, adding occupant protection.

- Wide VLT range (approx. 5–78%) and aesthetic choices — neutral, tinted or spectral/metallic looks to match OEM styling and local regulations.

Ultra-High Heat Rejection & Efficiency

99%+ UV Defense & Interior Preservation

TiN Precision & Nano-Ceramic Clarity

Magnetron Sputter & Spectral Styling

Safety & Anti-Shatter Protection

Seamless Connectivity & Day-Night Visibility

Product Structure

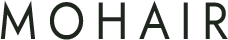

PROKHAR TiN Magnetron Sputtered Car Window Film

A. Outer hardcoat (scratch & weather resistant)

A cured hardcoat is applied to the exposed surface to resist scratches, chemicals and environmental wear. This preserves optical stability during cleaning and installation and reduces on-car abrasion. Hardcoats are typically roll-coated and cured in-line during manufacture.

B. Tone control layer

A very light tone or neutralizing layer adjusts perceived tint and ensures optical neutrality. For PROKHAR TiN lines we minimise dye content (keeps colour bias low) and rely on TiN/dielectric design to control visual appearance rather than heavy pigments.

C. Optical-interference / nano-ceramic + TiN sputtered stack

This is the functional heart of the film: alternating ultrathin TiN layers and dielectric (high/low refractive index) films are deposited by magnetron sputtering to form an optical interference stack. By precisely controlling layer thicknesses and spacing the stack:

- reflects/blocks IR and near-IR (reducing heat load),

- transmits visible light with low reflection and minimal colour shift, and

- maintains low haze / high clarity.

TiN provides the spectral functionality (absorption/reflection and plasmonic behaviour) while dielectric layers tune phase and protect the metal layers. This multi-layer approach is how PROKHAR achieve high IRR with lighter VLTs.

D. Tie-coat

A thin tie layer improves adhesion between the sputtered/coated stack and the PET carrier (or the downstream adhesive). This layer reduces delamination risk and increases long-term durability in automotive environments.

E. PET carrier

An optical-grade polyester (PET) film provides dimensional stability, the physical substrate for coatings and the primary optical base. For PROKHAR premium TiN films we balance handling, cut-ability and optical flatness (factory roll format).

F. Pressure-sensitive adhesive (PSA)

A transparent, UV-stable adhesive bonds the film to glass. The PSA is formulated to avoid yellowing, provide secure long-term adhesion, and allow eventual removal without residue when required.

G. Release liner

A protective release liner keeps the film clean in roll form and is stripped at the installer’s bench just prior to application.

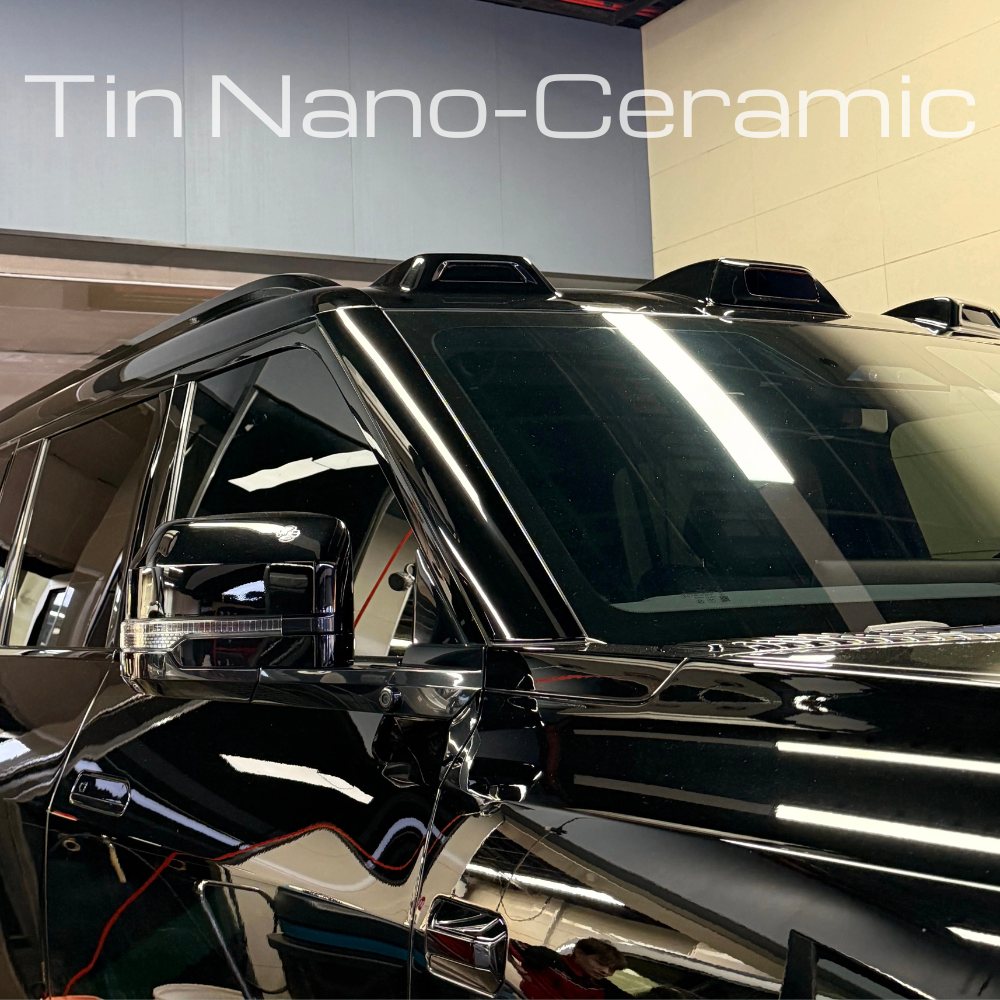

PROKHAR TiN Nano-Ceramic Car Window Film

A. Outer hardcoat (scratch & weather barrier)

A UV/thermally cured hardcoat protects the functional stack from abrasion, chemicals and weathering. It preserves surface gloss and prevents mechanical or environmental damage to the underlying sputtered/ceramic layers during handling and installation.

B. Optical overcoat

A transparent tuning layer that mutes metallic glare, controls visible reflection and refines the film’s perceived tone. It also acts as an interface between the hardcoat and the optical stack to maintain optical neutrality and consistent aesthetics.

C. Nano-ceramic functional layer

A dispersion of non-metallic nano-ceramic particles that increases IR absorption/scattering, improves thermal stability and reduces the metal layer’s sensitivity to oxidation. By adding targeted ceramic functionality the film raises overall TSER while enabling non-metallic signal-friendly options—core to PROKHAR’s high-end nano-ceramic strategy.

D. Dielectric optical stacks (multi-layer interference layers)

Alternating high/low refractive index dielectric layers tune phase relationships in the stack so the film selectively reflects NIR/short-wave IR while transmitting visible light with minimal colour shift. These interference layers enable precise spectral shaping (visible vs NIR) and are critical to achieving high IRR with low VLT impact.

E. TiN magnetron-sputtered functional layers

Ultra-thin TiN sputtered layers provide metallic-like selective reflection in the NIR while remaining relatively transparent in the visible band. When alternated with dielectrics, TiN enables strong NIR rejection, refined spectral curves and controlled colour bias—delivering the “spectral selectivity” that separates premium PROKHAR TiN films from dyed or bulk-metalized products.

F. Sealing dielectric layer

A dense oxide/nitride barrier prevents moisture and oxygen ingress to the metal/ceramic stack, improving corrosion resistance and long-term durability—particularly important for sputtered metal layers exposed to humid or coastal environments.

G. PET carrier

Optical-grade PET provides dimensional stability, handling strength and a flat optical substrate for sputtering and coating. PET thickness is selected to balance cut-ability, shrink behaviour and on-vehicle conformability.

H. Pressure-sensitive adhesive (PSA)

A transparent, UV-stable PSA bonds the film to glass. Formulated to resist yellowing, maintain peelable removability and ensure long-term adhesion without leaving residue.

I. Release liner

Protective liner keeps rolls clean and non-sticky during storage and shipping; it is peeled away immediately before installation.

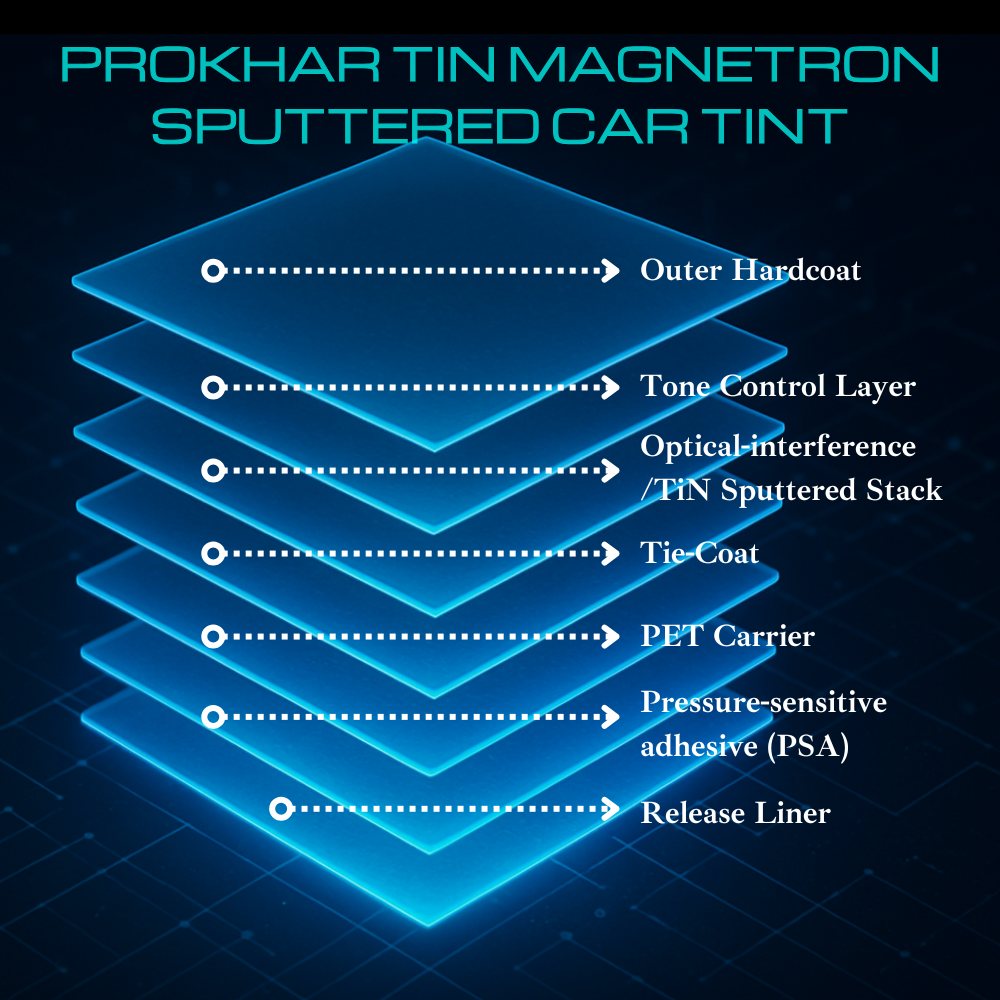

PROKHAR Magnetron-Sputtered Metal Film

A. Outer hardcoat (scratch & weather barrier)

A cured, abrasion-resistant topcoat that protects the functional stack from scratches, chemicals and environmental wear during handling, installation and service life.

B. Dielectric buffer

A thin dielectric primer that conditions the PET surface, improves wetting and adhesion for subsequent sputtered metal layers, and helps set initial phase relationships for the optical stack.

C. Functional metal layers(sputtered metals)

Ultra-thin magnetron-sputtered metal films (Ag, Au, Ti, Ni or alloys) that provide the core reflective/IR-blocking function. Layering and metal choice are tuned to shape NIR reflectivity and overall spectral response.

D. Optical interference layers

Alternating high/low refractive index dielectric coatings control interference effects — reducing mirror-like glare in visible bands, optimising visible light transmission, and preserving NIR blocking where needed.

E. Tie-coat

A dedicated tie layer that bonds the sputtered stack to the PET facestock and improves peel resistance, reducing delamination risk over long exposures.

F. PET carrier

Optical-grade polyester provides dimensional stability, cut/fit behaviour and the physical foundation for coatings. PROKHAR premium sputtered lines use facestock specs matched for reliable installability.

G. Pressure-sensitive adhesive (PSA)

A transparent, UV-stable adhesive formulated for secure glass bonding, clean removability and long term resistance to yellowing and temperature cycling.

H. Release liner

Protective silicone liner keeps the roll clean and non-tacky until application; it’s removed immediately before installation.

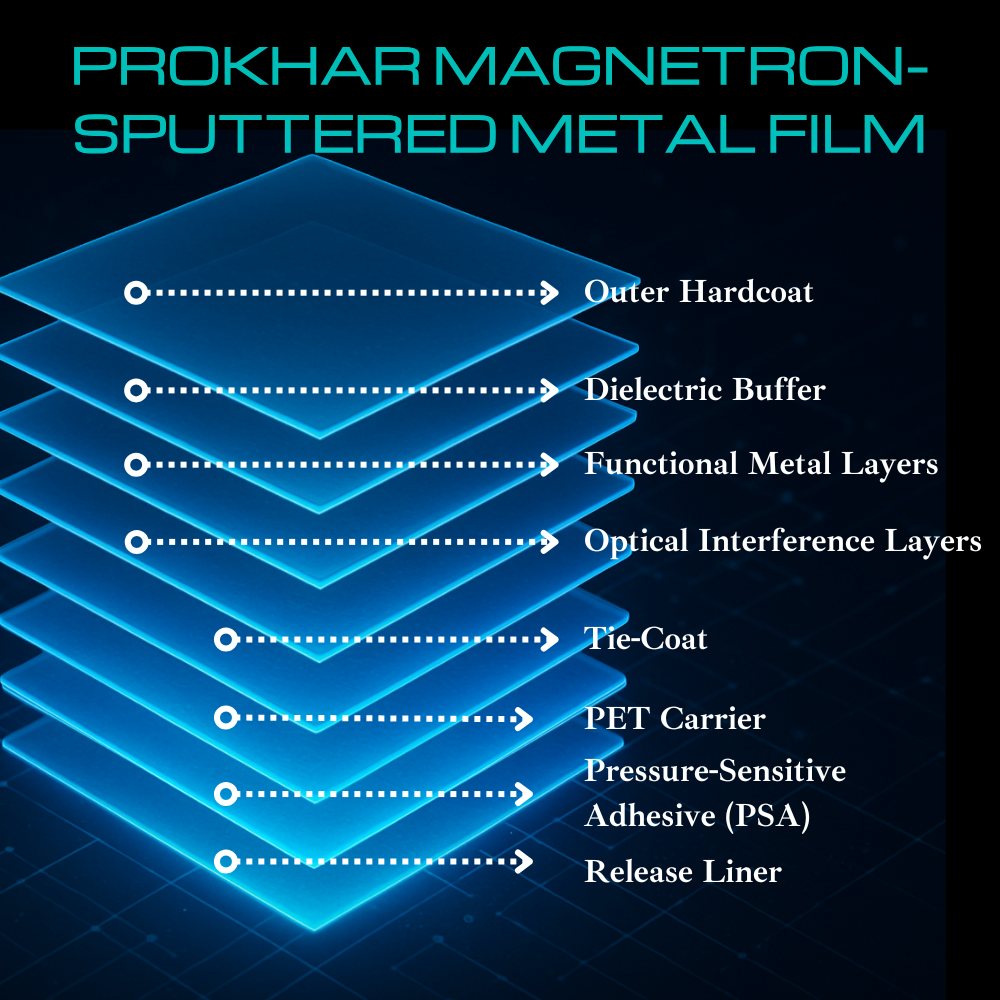

PROKHAR MystGlow Series Optical Tint

A. Outer hardcoat (scratch & weather barrier)

A cured, abrasion-resistant topcoat protects the delicate optical stack from scratches, chemicals and weathering during handling, installation and vehicle life — essential for preserving the film’s fine structural colour and surface gloss.

B. Tie-coat (overcoat)

A thin transparent interlayer that evens out refractive transitions, improves adhesion between the hardcoat and the interference stack, and refines the visible reflectance (reducing unwanted glare while maintaining the colour effect).

C. Multilayer interference stack

The colour engine: dozens–hundreds of alternating ultrathin polymer layers with controlled thickness and refractive-index contrast. These precisely tuned layers use optical interference to reinforce or suppress selected wavelengths, producing angle-sensitive “chameleon” colours (not pigment). Because the stack is non-metal, it preserves signal compatibility and delivers stable colour shifts under different light and viewing angles.

D. PET / polyester facestock

Optical-grade PET provides the flat optical substrate, mechanical strength and roll-handling behaviour. Balances conformability, cutting, and long-term dimensional stability during installation and service.

E. Pressure-sensitive adhesive (PSA)

A UV-stable, non-yellowing adhesive designed for automotive glazing: strong long-term bond, removable without residue when required, and tolerant of temperature cycling and outdoor UV exposure.

F. Release liner

Liner protects the adhesive during storage and transport; removed immediately before installation.

WARRANTY COVERAGE

- What’s covered: manufacturing defects such as rapid color change under normal use. Coverage includes replacement of defective film and re-installation where applicable.

- Term / tiers: All lines carry a multi-year limited warranty. Exact term is regionally defined.

- Limitations & exclusions: normal wear (minor surface scratches), damage caused by external impacts, unauthorized removal/peeling, and fading within expected tolerances may be excluded.

- How to claim: Keep the proof of purchase and contact your regional PROKHAR distributor or partner shops; validated claims will be handled with repair, replacement or pro-rated service.

DAILY CARE AND MAINTENANCE INSTRUCTIONS:

Post-install “do not” window checklist (first 1–14 days)

- Do not roll down windows for the first 48–72 hours (minimum) — many premium manufacturers recommend waiting up to 5–7 days depending on climate and product. This ensures the adhesive sets and edges bond.

- Delay cleaning the film for at least 7 days. Avoid power washers and automated car washes during the cure period.

Routine cleaning & long-term care (after cure)

- Use mild soap and lukewarm water with a soft microfiber or lint-free cloth or sponge. Rinse and blot dry — standard household cleaners that are non-abrasive are acceptable.

- Avoid ammonia, alcohol and abrasive cleaners (these can attack adhesives or coatings). Also avoid scouring pads or razor blades on the film.

- No stickers or adhesives applied to filmed surfaces for at least the first week; peeling at edges will invite delamination.

- If hazing or water bubbles appear: small hazy areas or minor water pockets can be normal during curing and typically clear within weeks; prolonged bubbling or edge lifting should be inspected by your installer.

Maintenance tips for fleets & resellers

- Provide customers with a one-page care card (VLT, UVR/IRR specs + cure times + cleaning do’s/don’ts) at handover — transparency reduces warranty calls and builds trust.

- Recommend ceramic/TiN lines for customers who require zero signal interference; advise fleet managers to log installations in your warranty portal for easy service.

Price Tiers & Specialty Line

Luxury tier — Tin Magnetron-Sputtered

Orca Series is PROKHAR’s flagship luxury car window film. Built on precision magnetron-sputtered Titanium Nitride (TiN) layers on optical-grade PET, Orca delivers a dense, corrosion-resistant coating with exceptional thermal control and ultra-low colour shift.

- Default construction: 2 mil sputtered TiN.

- Performance highlights (targeted for premium showrooms and high-end dealers): UVR 99%, IRR 99%, optical clarity 0.75–0.9.

- Designed for customers who want showroom aesthetics, long-term stability and the maximum heat-rejection benefits of sputtered TiN without sacrificing clarity. This series is ideal for luxury fleets, OEM match projects and high-margin retail installs.

Premium tier — Tin Nano-Ceramic

Our premium tier brings TiN’s spectral benefits into non-metal, nano-ceramic constructs for buyers who want best-in-class comfort plus “signal-friendly” performance.

- Humpback Series — UVR 99% / IRR 99%, clarity 0.1–0.7.

- Narwhal Series — UVR 99% / IRR 95%, clarity 0.1–0.6.

- Minke Series — UVR 99% / IRR 92%, clarity <1%.

All Premium films use advanced TiN-enhanced nano-ceramic coatings on optical PET: ultra-low haze, stable colour, near-zero RF/GPS interference and consistent performance day & night. These are the go-to SKUs for busy detailers and larger shops that need a high-turnover, high-margin ceramic product that competes with top global premium lines.

Economy tier — Value Nano-Ceramic

Designed for price-sensitive channels and aggressive market entry, Sturgeon Series is factory-supplied in roll quantities to keep unit cost low and lower the barrier for distributors and small installers. Default 2 mil; engineered as a high-performance nano-ceramic with UVR 99%, IRR ≥ 90% and clarity 1.5–2.5. Sturgeon is the “intro & scale” SKU — good heat rejection, dependable longevity, and simple logistics (no MOQ limits) so partners can quickly list and move inventory while protecting margins.

Special tier — Metal Magnetron Sputtered

For customers who prefer the high-reflective, metallic look and heat-reflective behavior of sputtered metal films:

- TitanSheen — multi-metal sputter stacks (Ti, Ni, Ag variants) — UVR 99% / IRR ~95%, clarity ~1.5–2.

- SilverSheen — single-silver sputter finish — UVR 99% / IRR ~90%, clarity 0.7–1.

Both are default 2 mil sputtered constructions delivering pronounced IR reflection, a distinct metallic aesthetic and strong privacy. Recommend to style-driven installers and shops that offer premium “visual upgrade” packages.

Special tier — Optical (Color & Effect)

MystGlow is PROKHAR’s creative optical line: multi-layer spectrally-selective coatings that produce angle-dependent colour shifts and refined metallic sheens while keeping visible clarity high and heat rejection strong. Default 2 mil. Options:

- MystGlow · Anole — bold, shifting colours (Aurora green, Phantom rose, Imperial purple, Blue-sheen) for trend-conscious customers.

- MystGlow · Skink — elegant spectral blues & greens with a more approachable price point.

These films use multilayer optical stacks to combine brightness, colour play and thermal performance — but tailored for aesthetic impact and aftermarket differentiation. Perfect for specialty shops, styling boutiques and customers seeking standout looks.

Less Heat, More Focus

Extreme Safety & Shatter Protection

PROKHAR window films use multi-layer adhesive laminates and high-strength polymer films that hold glass fragments together on impact, dramatically reducing shard scatter and injury risk. The robust construction adds a protective barrier against break-ins and road debris — a true safety upgrade for fleet, retail and luxury installs.

Superior Heat Rejection & Uv Defense

Advanced optical stacks and TiN/ceramic technologies enable IR rejection up to 99% and ≥99% UV block, keeping cabin temperatures lower, reducing A/C load and preventing interior fading, cracking or discoloration. Designed to balance total solar energy rejection (TSER) with visual comfort, PROKHAR tints deliver cool cabins without darkening your view.

Enhanced Privacy Without Compromise

Available across a wide VLT range (~5–78%) and in neutral, tinted or spectral bases (including green/blue options), PROKHAR film provides tailored privacy and refined styling. Spectrally selective and metallic finishes offer angle-shift color effects for customers who want distinctive looks without sacrificing clarity or compliance.

Seamless Connectivity — Zero Signal Interference

PROKHAR tinting is engineered to preserve GPS, mobile, radio and Bluetooth reception. Even our magnetron-sputtered metal formulas are optimized to avoid EMI so drivers keep crystal-clear communications and navigation while enjoying premium thermal performance.

Crystal-Clear Day & Night Visibility

Optical-grade PET and precision coatings keep haze as low as 0.1–2%, ensuring distortion-free sightlines in all lighting conditions. High-transmission formulations balance safety, visibility and style so drivers enjoy clear views by day and confident visibility at night.

Tint that sells — priced to move.

Distributors get protected pricing and OEM options — request a tailored partner quote for your region.