Metal Magnetron Sputtered

Special Tier

PROKHAR Tint — Drive Cool, Stay Secure

The PROKHAR Distinctive family brings two magnetron-sputtered metal film lines for customers who want the unmistakable performance and aesthetic of precision metal coatings: TitanSheen Series and SilverSheen Series. Both films are produced as 2-mil constructions on optical-grade PET and finished with a durable hardcoat and proven adhesive system for reliable installs and day-to-day durability. These multi-layer sputtered metal stacks are engineered to reflect near-infrared (NIR) energy strongly while preserving visible light transmission and reducing mirror-like glare — ideal for buyers who prioritize thermal reflection and a refined metallic appearance.

- TitanSheen — magnetron-sputtered metal (multi-layer), UVR 99% · IRR 95% · clarity 1.5–2.0 (haze).

- SilverSheen — magnetron-sputtered (single-silver style), UVR 99% · IRR 90% · clarity 0.7–1.0 (haze).

(Technical note: sputtered metal films use vacuum magnetron sputtering to deposit nanometer-thin metal/dielectric layers; this enables strong IR/NIR reflection with controlled visible appearance.)

KEY FEATURES & ADVANTAGES

- True thermal reflection — engineered for IR/NIR rejection: Multi-layer magnetron sputtering concentrates reflectivity where it matters (IR/NIR), giving strong heat reflection while allowing pleasing visible transmission. TitanSheen targets very high NIR reflection for maximum cabin cooling; SilverSheen balances high IR reflection with a cleaner aesthetic.

- Precision metal layer control — high performance with tuned appearance: Sputtering deposits nanometer-thin metal/dielectric stacks with exact thickness control, enabling designers to tune visible reflectance, color cast and NIR block independently. Metallic look without the heavy mirror finish of older metallized films.

- Strong UV protection and material stability: Both series deliver ≥99% UVR to protect interiors from fading and occupants from UV exposure. Sputtered metal stacks paired with quality PET and hardcoat provide long-term color stability and resistance to environmental degradation when properly finished.

- Optimized optical behavior — lower glare, clearer sightlines: Engineering the stack (metal + dielectric layers) reduces internal reflection and unwanted mirror effect, producing usable daytime/nighttime visibility and acceptable haze figures for each SKU. SilverSheen targets lower haze (0.7–1.0) for clearer sight; TitanSheen trades a slightly higher haze (1.5–2.0) for stronger IR reflection.

- Installer-friendly handling & everyday durability: Sputtered films from modern production lines are finished with hardcoats and stable adhesives to make cutting, squeegeeing and edge-seaming predictable for professional installers. Finished sputtered products offer consistent on-glass behavior and practical scratch resistance for daily use.

- Clear channel positioning for specific buyer groups

- TitanSheen — for customers who want maximal thermal reflection (ideal for hot-climate fleets, executive vehicles, premium retail installs).

- SilverSheen — for customers who want the prefer higher visual clarity and a more neutral appearance (ideal for style-conscious owners wanting visible clarity and IR performance).

TECHNICAL SPECIFICATIONS

| PROKHAR Metal Magnetron Sputtered Car Tint(1.52*30m) | ||

|---|---|---|

| Series | TitanSheen Series | SilverSheen Series (single-silver sputter) |

| Model | TS–05 / 15 / 25 / 35 / 70 / 75 | SS–05 / 15 / 25 / 35 / 60 / 70 |

| Total Thickness | 2MIL ± 0.2 | 2MIL ± 0.2 |

| VLT Options (%) | 05 / 15 / 25 / 35 / 70 / 75 | 05 / 15 / 25 / 35 / 60 / 70 |

| UVR | 98% – 99% | 98% – 99% |

| IRR | 95% ± 3% | 90%±3% / 90%±3% / 90%±3% / 92%±3% / 97%±3% / 91%±3% |

| Total Solar Energy Rejection (TSER) (%) | 92 / 87 / 85 / 77 / 60 / 55 | 88 / 87 / 84 / 75 / 66 / 56 |

| Haze (Without Release Film) (%) | 1.59 / 1.92 / 2.2 / 2.2 / 1.79 / 1.82 | 0.79 / 1.07 / 0.73 / 1.07 / 1.38 / 1.06 |

| Baking Film Shrinkage Characteristics | Four-sided Shrinkage Ratio | |

| Warranty (Year) | 5 | 5 |

Ultra-High Heat Rejection & Efficiency

99%+ UV Defense & Interior Preservation

High Clarity & Spectral Styling

Safety & Anti-Shatter Protection

Seamless Connectivity & Day-Night Visibility

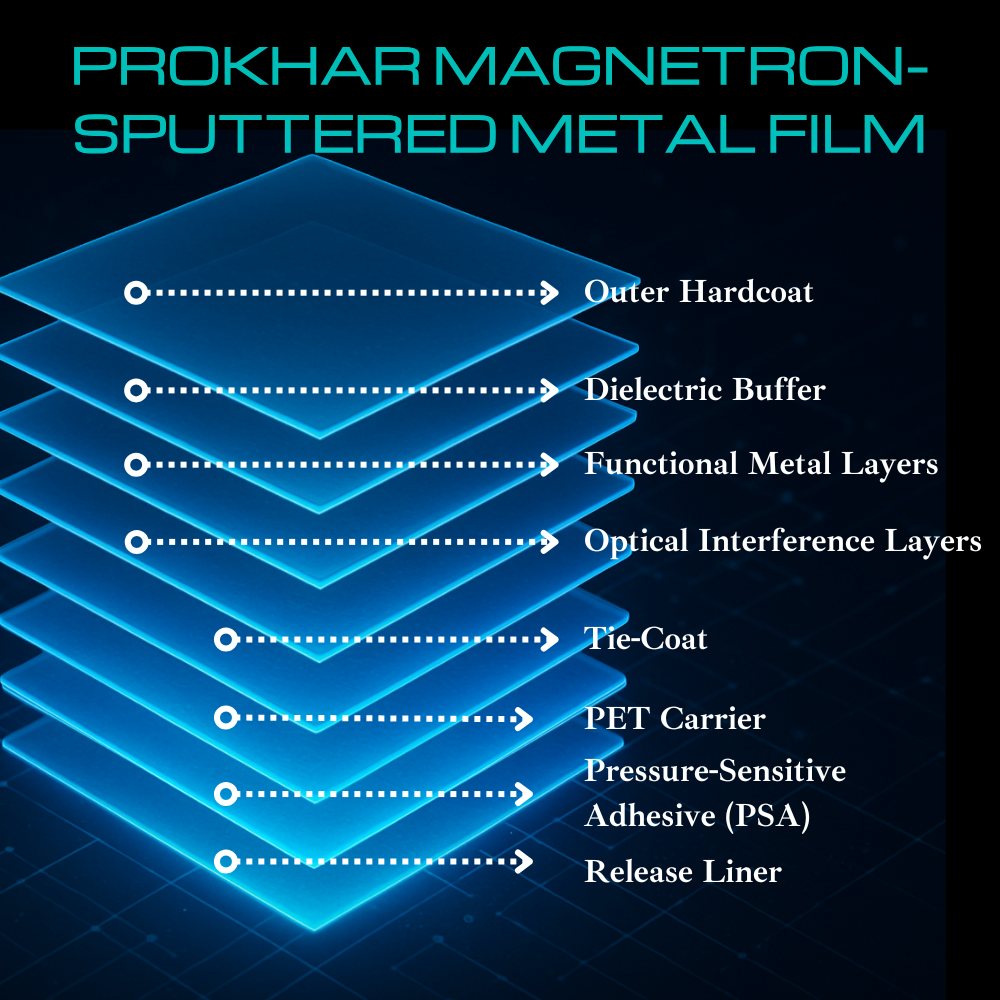

Product Structure

PROKHAR Magnetron-Sputtered Metal Film

A. Outer hardcoat (scratch & weather barrier)

A cured, abrasion-resistant topcoat that protects the functional stack from scratches, chemicals and environmental wear during handling, installation and service life.

B. Dielectric buffer

A thin dielectric primer that conditions the PET surface, improves wetting and adhesion for subsequent sputtered metal layers, and helps set initial phase relationships for the optical stack.

C. Functional metal layers(sputtered metals)

Ultra-thin magnetron-sputtered metal films (Ag, Au, Ti, Ni or alloys) that provide the core reflective/IR-blocking function. Layering and metal choice are tuned to shape NIR reflectivity and overall spectral response.

D. Optical interference layers

Alternating high/low refractive index dielectric coatings control interference effects — reducing mirror-like glare in visible bands, optimising visible light transmission, and preserving NIR blocking where needed.

E. Tie-coat

A dedicated tie layer that bonds the sputtered stack to the PET facestock and improves peel resistance, reducing delamination risk over long exposures.

F. PET carrier

Optical-grade polyester provides dimensional stability, cut/fit behaviour and the physical foundation for coatings. PROKHAR premium sputtered lines use facestock specs matched for reliable installability.

G. Pressure-sensitive adhesive (PSA)

A transparent, UV-stable adhesive formulated for secure glass bonding, clean removability and long term resistance to yellowing and temperature cycling.

H. Release liner

Protective silicone liner keeps the roll clean and non-tacky until application; it’s removed immediately before installation.

Tint that sells — priced to move.

Distributors get protected pricing and OEM options — request a tailored partner quote for your region.