CelestFlux Series

Luxury Tier

PROKHAR PPF — Not Just Film, Peace of Mind

PROKHAR CelestFlux — flagship Luxury Line PPF series designed to compete with international premium brands. Built around a 7.5mil global-standard polycaprolactone TPU (custom thicker options available), CelestFlux combines 100% Lubrizol high-grade TPU substrate with a custom Japanese Cashew topcoat and Ashland adhesive to deliver a class-leading balance of durability, clarity and installability. Engineered for installers who demand seamless conformance to complex body curves and for high-end dealers seeking a premium SKU, CelestFlux offers exceptional tensile strength and elongation, best-in-class tear and impact resistance, ultra-high visible light transmittance and long-term anti-yellowing stability. Paired with PROKHAR premium packaging and local precision production on high-end Davis calendaring lines, this car paint protection film is positioned as PROKHAR’s top flagship to service professional chains, premium distributors and specialist detail shops.

Designed performance highlights include reliable self-healing under heat, Ashland adhesive for secure bond and residue-free removal, and a dual nanoscopic hydrophobic system from Japan that provides superior resistance to acid, alkali and salt corrosion while maintaining showroom gloss. Tested across extreme climates (operational range −40 °C to 150 °C), CelestFlux retains flexibility in cold starts and persistence under thermal stress — delivering professional-grade protection and high-tech visual appeal for any vehicle.

KEY FEATURES & ADVANTAGES

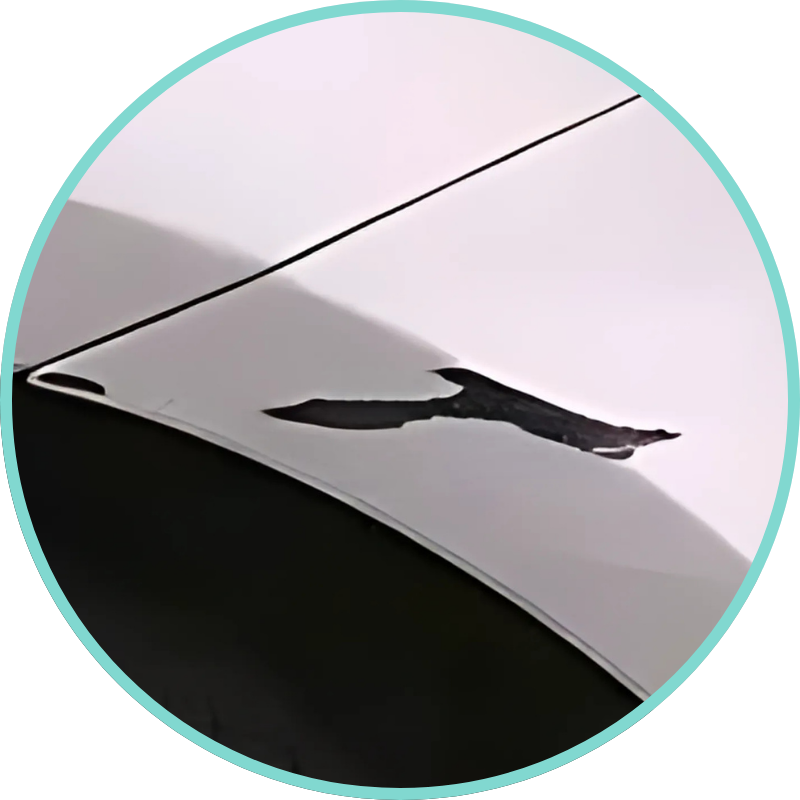

- Extreme durability: scratch, impact and puncture resistance for extended service life.

- Superior mechanical performance: high tensile strength and elongation — remains flexible even at low temperature.

- Long-term non-yellowing: sustained transparency and gloss under UV exposure.

- Comprehensive corrosion resistance: defends against acid, alkali and salt fog.

- Wide environmental compatibility: reliable operation from −40 °C to 150 °C (suitable for harsh climates, sandstorms, coastal conditions).

- Self-healing: heat-activated repair for minor surface damage.

- Local precision manufacturing: produced on high-precision Davis calendering lines for consistent quality, fast fulfilment and efficient inventory control.

TECHNICAL SPECIFICATIONS

PROKHAR Polycaprolactone TPU PPF (1.52*15m) Luxury Line – CelestFlux Series | |

|---|---|

| Model | CF-PK1 |

| TPU Substrate | Lubrizol |

| Thickness | 7.5mil |

| Finish Type | Clear, Glossy |

| Glue | Ashland |

| Self-Healing | Heat Repair |

| Water Action | Hydrophobic |

| Elongation at break, % (Machine direction) | ≥400 |

| Tensile Strength | ≥30 MPa |

| Tear Strength | ≥78 KN/M |

| Luminous transmittance | ≥93% |

| Gloss (60°) | ≥98.4 GU |

| Gloss retention after Xenon 1000 h (ΔE, CIELAB) | ≤1.5 |

| Aging | QUV 3000h – No detrimental effect |

| Warranty (years) | 10 |

Self-Healing & Mirror-Gloss

Nano-Hydrophobic Surface

UV-Stable, Anti-Yellow Formulation

Rock-Chip & Impact Defense

Installer-Friendly Fit & Low Shrinkage

Trade-Grade Consistency & Support

Mud and dirt

Wind and sand splash

Acid rain corrosion

Animal faecal residues

Accidental scratching

Oxidised ageing

Malicious scratching

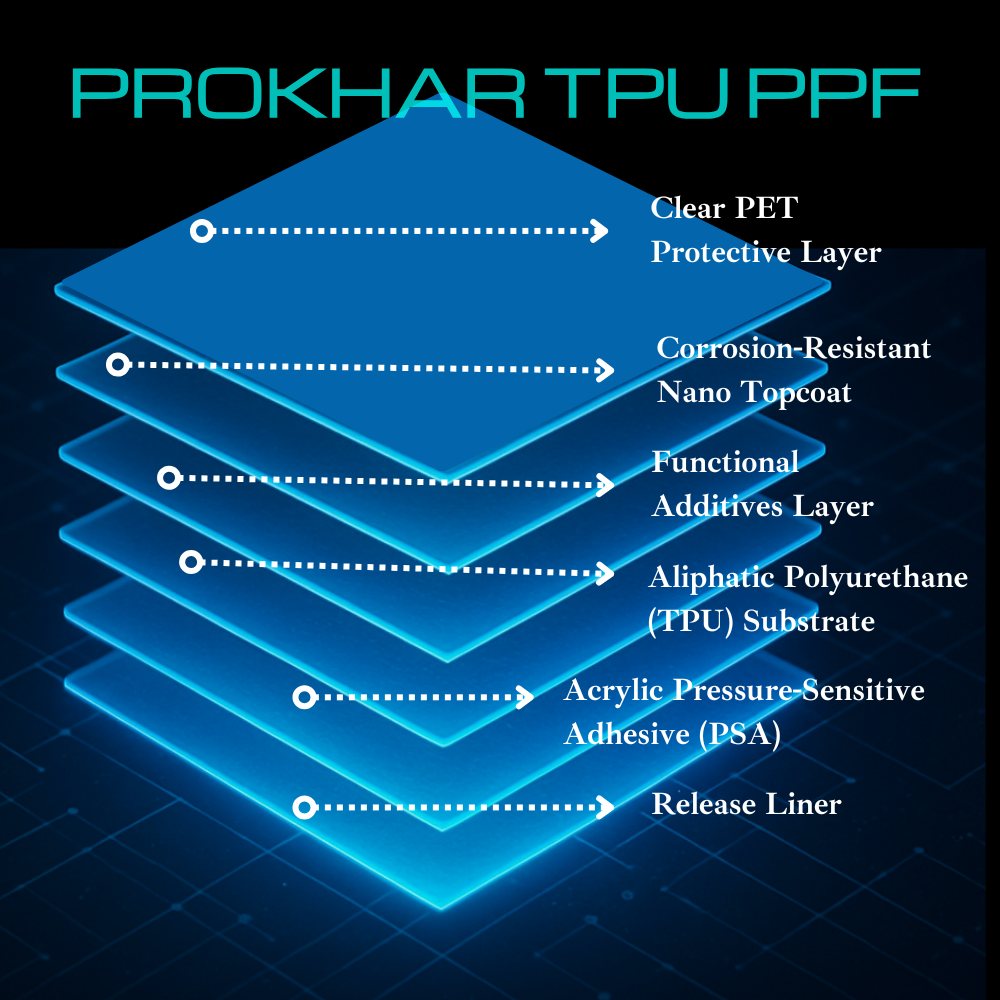

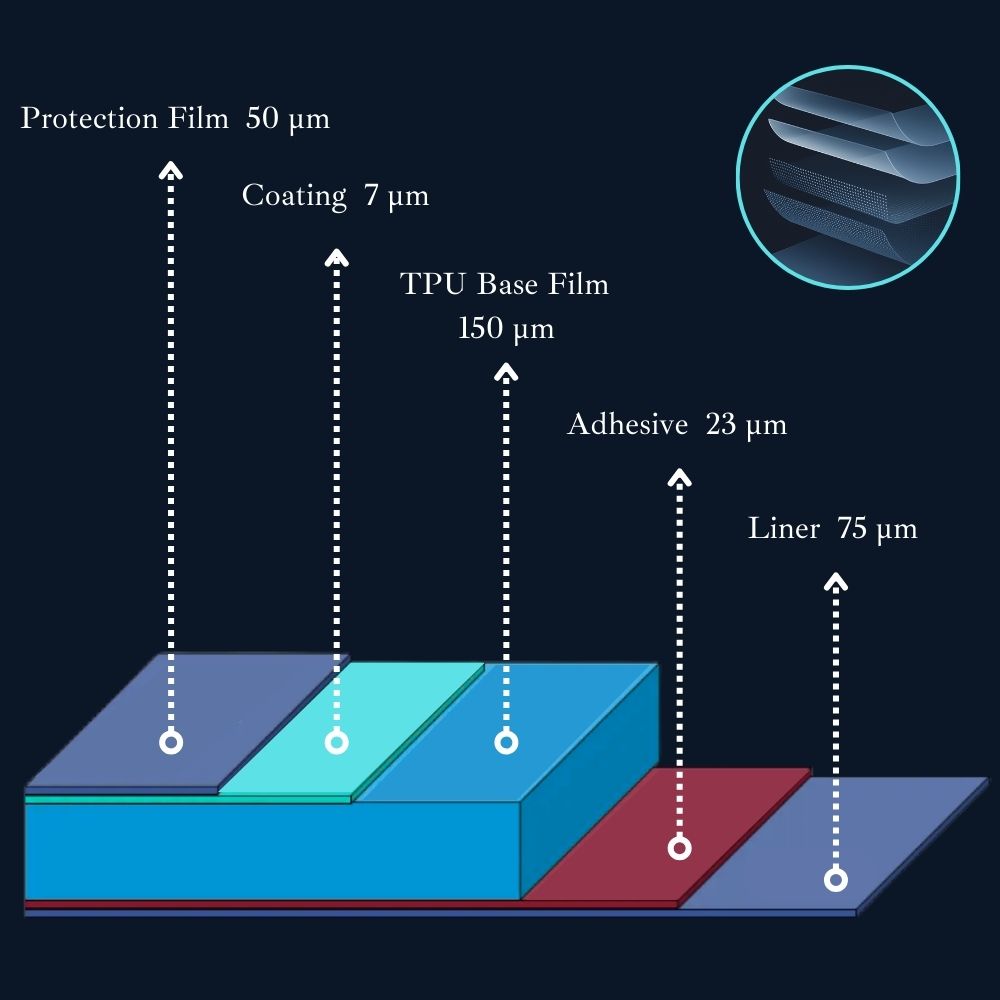

Product Structure

PROKHAR Car PPF

Clear PET Protective Layer (Top removable guard during manufacture & transport)

- Thin transparent PET film applied as a temporary protective barrier.

- Shields the underlying functional topcoat during cutting, roll handling and shipping; prevents micro-abrasions and contamination before final installation.

Topcoat — Corrosion-Resistant Nano Topcoat + Self-Healing Coating

- High-performance nano topcoat manufactured in Japan, enhanced with ceramic nanoparticles and a self-healing polymer matrix.

- Provides hydrophobic/oleophobic surface properties, superior resistance to acids/alkalis/salts, surface scratch resistance and thermal self-healing for light abrasions when heat-activated.

- Ceramic nano-fillers increase stain resistance and long-term gloss retention — a key selling point for premium car clear bra customers.

Functional Additives Layer

- Nanocoatings and high-gloss treatments integrated into or atop the topcoat.

- Boosts initial and long-term gloss, improves surface smoothness for easier cleaning and better visual depth.

- Enhanced showroom finish that helps installers demonstrate value to end customers.

Aliphatic Polyurethane (TPU) Substrate — Core Protective Layer

- High-grade aliphatic TPU formulated for low yellowing, high elongation and impact energy absorption.

- Primary protective body of the film — provides elasticity for complex curves, impact resistance against stone chips, tear resistance and optical transparency.

- Aliphatic chemistry offers superior UV/yellowing stability versus aromatic TPUs, ensuring clarity and color-fast performance over years.

Acrylic Pressure-Sensitive Adhesive (PSA)

- High-performance acrylic adhesive supplied to PROKHAR spec (Ashland/Henkel grade).

- Secure, long-lasting bond to automotive paint while allowing repositioning during installation; engineered for low residue on removal and minimal paint interaction.

- Installer confidence through consistent tack, clean removability and reduced callbacks.

Release Liner (Backing for storage & cutting)

- Silicone-coated release liner that protects the PSA until application.

- Facilitates storage, precision cutting and transport; peeled away immediately before install.

- Stable, flat liners that reduce mis-cuts and speed pre-cut workflows for distributors and installers.

Bulk or single-job? We’ve got both.

Tell which PPF series and price tier you need — get a custom quote that suits your shop or distribution plan.