StarLustre Series

Standard Tier

PROKHAR PPF — Not Just Film, Peace of Mind

StarLustre is the Standard tier in PROKHAR’s PPF lineup, engineered as the go-to, high-turnover solution for larger automotive-detailing shops and regional distributors. Built around a 7.5 mil thermoplastic TPU core (available in 8.5 mil and 9.5 mil options), StarLustre balances cost-efficiency with proven premium protections: heat-activated self-healing and an instant-repair variant are both available to match workshop workflows and customer expectations. Each roll is precision-engineered to conform to the most complex body curves and trim details while guaranteeing residue-free removal.

The material system combines high-performance thermoplastic TPU elasticity with Ashland’s advanced adhesive technology, delivering superior tensile strength, high elongation at break, and elevated tear and puncture resistance. A fifth-generation Japanese nano-supercoating enhances resistance to acid rain, salt, and UV-induced yellowing while continuing to preserve gloss and optical clarity. StarLustre is positioned as the practical, best-selling line that lets shops scale operations without sacrificing the look and protection customers expect from a premium car paint protection film.

KEY FEATURES & ADVANTAGES

- High-grade design: Improved conformability and impact resistance for everyday and demanding use.

- Multiple thicknesses: Available in 7.5 mil (default), with 8.5 mil and 9.5 mil options to match front-end, bumper, or full-wrap protection strategies; choose heat repair or instant repair variants.

- Thermoplastic TPU substrate: Outstanding tensile strength and elongation for superior load bearing, tear and puncture resistance, and long-term dimensional stability.

- 5th-generation Japanese nano supercoating: Exceptional resistance to acid, alkali and salt; minimizes yellowing and sustains mirror-like gloss; supports heat-activated self-healing.

- Ashland high-performance adhesive: Strong, secure bonding with clean, residue-free removal; solvent and weather resistant; resists insect and bird-drop degradation.

- Perfect fit, zero residue: Molecular-level flow and installation-grade processing deliver bubble-free, edge-stable application across complex curves and recessed details.

- Premium visual finish: High-gloss mirror effect that elevates vehicle aesthetics while remaining tough against stone chips, scratches, UV and daily wear.

- Operational reliability: Engineered for real-world climates and heavy workshop use — a proven choice for shops that need a dependable, fast-moving SKU.

TECHNICAL SPECIFICATIONS

PROKHAR Polycaprolactone TPU PPF (1.52*15m) Standard Tier — StarLustre Series | |||||

|---|---|---|---|---|---|

| Model | SL-PK1 | SL-PK2-IH | SL-PK3 | SL-PK-X | SL-PK-E |

| TPU Substrate | Miracll Chemicals | Miracll Chemicals | Covestro | Covestro | Covestro |

| Thickness | 7.5mil | 7.5mil | 7.5mil | 8.5mil | 9.5mil |

| Finish Type | Clear, Glossy | Clear, Glossy | Clear, Glossy | Clear, Glossy | Clear, Glossy |

| Glue | Ashland | Henkel | Ashland | Ashland | Ashland |

| Self-Healing | Heat Repair | Instant Healing | Heat Repair | Heat Repair | Heat Repair |

| Water Action | Hydrophobic | Hydrophobic | Hydrophobic | Hydrophobic | Hydrophobic |

| Elongation at break, % (Machine direction) | ≥310 | ≥300 | ≥310 | ≥330 | ≥400 |

| Tensile Strength | ≥28 MPa | ≥23 MPa | ≥25 MPa | ≥25 MPa | ≥25 MPa |

| Tear Strength | ≥62 KN/M | ≥61 KN/M | ≥61 KN/M | ≥63 KN/M | ≥63 KN/M |

| Luminous transmittance | ≥93% | ≥92% | ≥92% | ≥92% | ≥93% |

| Gloss (60°) | ≥95 GU | ≥91 GU | ≥91 GU | ≥91 GU | ≥91 GU |

| Gloss retention after Xenon 1000 h (ΔE, CIELAB) | ≤1.8 | ≤2 | ≤2 | ≤2 | ≤2 |

| Aging | QUV 1500h – No detrimental effect | QUV 1000h – No detrimental effect | QUV 1500h – No detrimental effect | QUV 1500h – No detrimental effect | QUV 1500h – No detrimental effect |

| Warranty (years) | 6 | 6 | 7 | 7 | 7 |

Self-Healing & Mirror-Gloss

Nano-Hydrophobic Surface

UV-Stable, Anti-Yellow Formulation

Rock-Chip & Impact Defense

Installer-Friendly Fit & Low Shrinkage

Trade-Grade Consistency & Support

Mud and dirt

Wind and sand splash

Acid rain corrosion

Animal faecal residues

Accidental scratching

Oxidised ageing

Malicious scratching

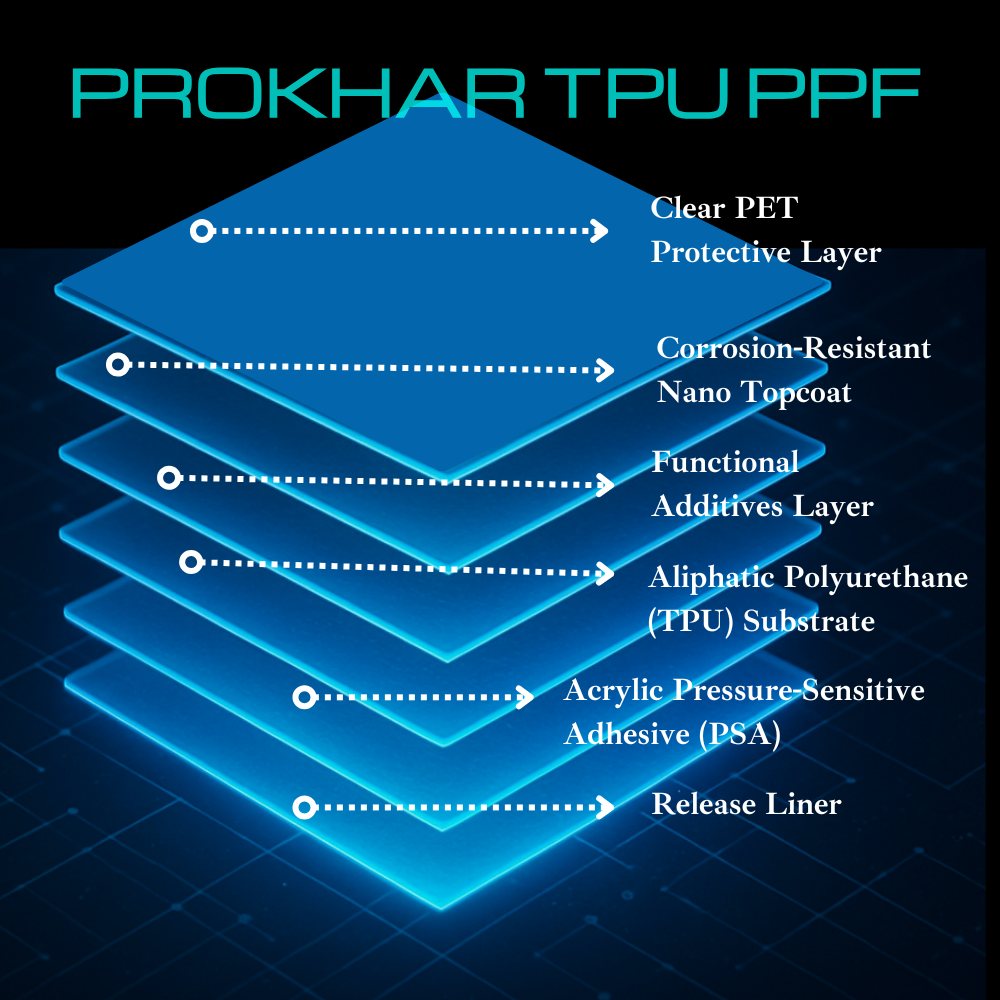

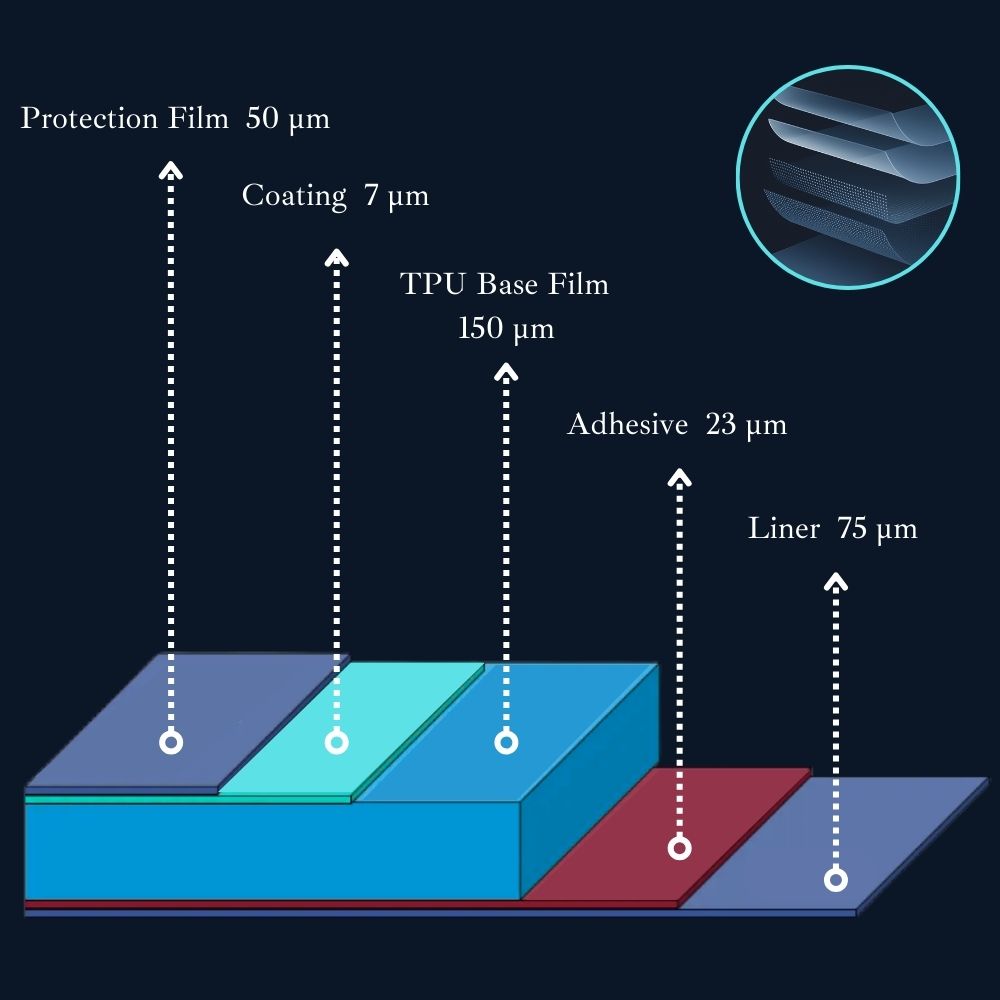

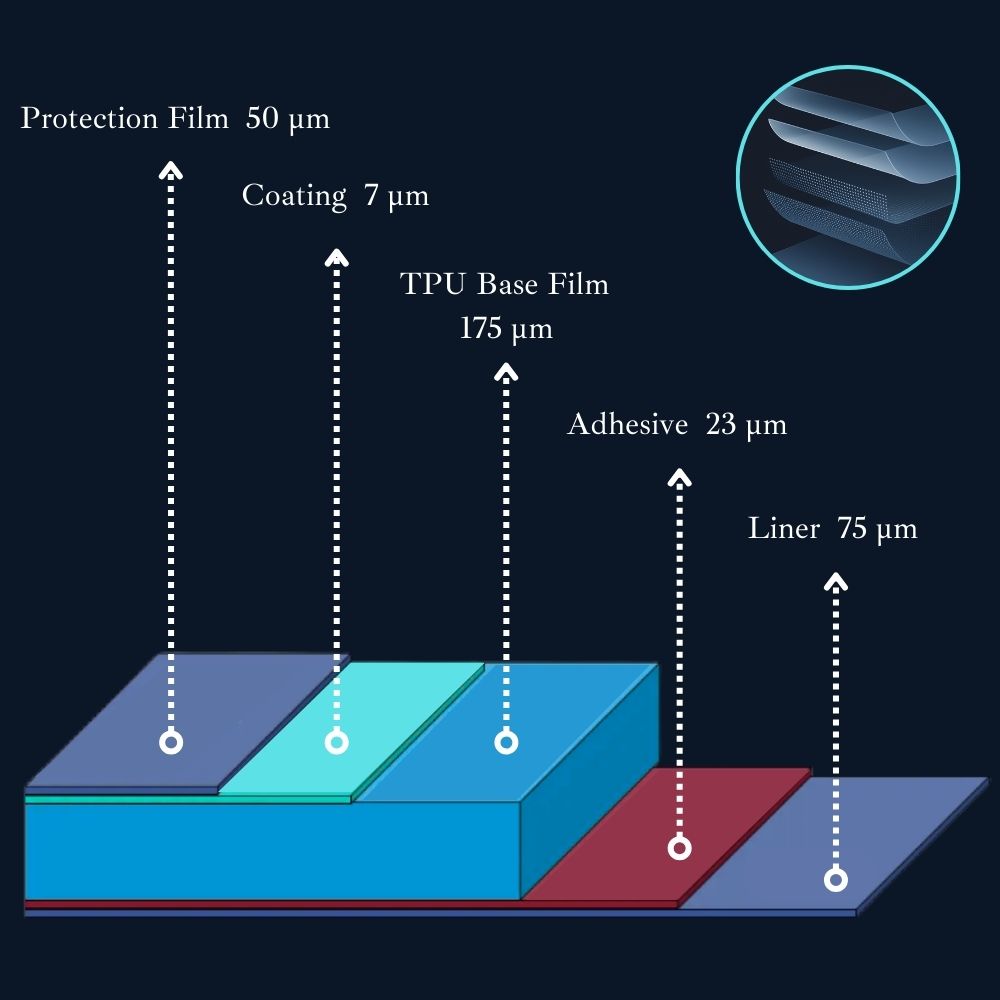

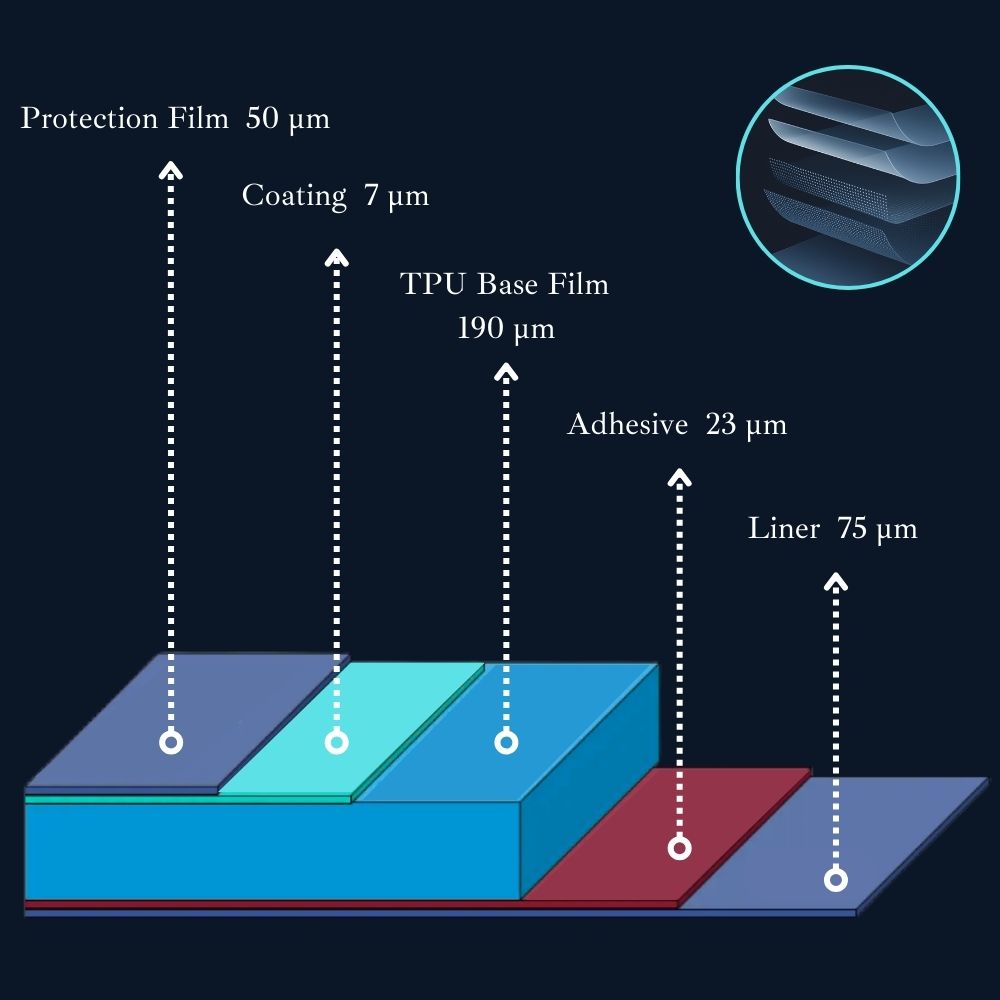

Product Structure

PROKHAR Car PPF

Clear PET Protective Layer (Top removable guard during manufacture & transport)

- Thin transparent PET film applied as a temporary protective barrier.

- Shields the underlying functional topcoat during cutting, roll handling and shipping; prevents micro-abrasions and contamination before final installation.

Topcoat — Corrosion-Resistant Nano Topcoat + Self-Healing Coating

- High-performance nano topcoat manufactured in Japan, enhanced with ceramic nanoparticles and a self-healing polymer matrix.

- Provides hydrophobic/oleophobic surface properties, superior resistance to acids/alkalis/salts, surface scratch resistance and thermal self-healing for light abrasions when heat-activated.

- Ceramic nano-fillers increase stain resistance and long-term gloss retention — a key selling point for premium car clear bra customers.

Functional Additives Layer

- Nanocoatings and high-gloss treatments integrated into or atop the topcoat.

- Boosts initial and long-term gloss, improves surface smoothness for easier cleaning and better visual depth.

- Enhanced showroom finish that helps installers demonstrate value to end customers.

Aliphatic Polyurethane (TPU) Substrate — Core Protective Layer

- High-grade aliphatic TPU formulated for low yellowing, high elongation and impact energy absorption.

- Primary protective body of the film — provides elasticity for complex curves, impact resistance against stone chips, tear resistance and optical transparency.

- Aliphatic chemistry offers superior UV/yellowing stability versus aromatic TPUs, ensuring clarity and color-fast performance over years.

Acrylic Pressure-Sensitive Adhesive (PSA)

- High-performance acrylic adhesive supplied to PROKHAR spec (Ashland/Henkel grade).

- Secure, long-lasting bond to automotive paint while allowing repositioning during installation; engineered for low residue on removal and minimal paint interaction.

- Installer confidence through consistent tack, clean removability and reduced callbacks.

Release Liner (Backing for storage & cutting)

- Silicone-coated release liner that protects the PSA until application.

- Facilitates storage, precision cutting and transport; peeled away immediately before install.

- Stable, flat liners that reduce mis-cuts and speed pre-cut workflows for distributors and installers.

Bulk or single-job? We’ve got both.

Tell which PPF series and price tier you need — get a custom quote that suits your shop or distribution plan.