TiN Magnetron Sputtered

Luxury Tier

PROKHAR Tint — Drive Cool, Stay Secure

Orca Series is PROKHAR’s Luxury-tier car window film engineered around precision vacuum-sputtered titanium-nitride (TiN) nano-layers on an optical-grade PET substrate. The Orca Series uses advanced magnetron sputtering to embed high-density TiN/ dielectric stacks that deliver spectrally-selective solar control: extreme infrared rejection with minimal visible light reflection and neutral in-glass appearance. Default film thickness is 2 mil; surface hardcoat and a proven adhesive system are applied to improve scratch resistance and installer handling. Designed for high-end dealers and national chains, Orca ships with premium PROKHAR packaging options for a luxury channel presentation.

KEY FEATURES & ADVANTAGES

1. Industry-leading solar performance

- Up to 99% UV and exceptional IR rejection — TiN sputtered stacks are tuned to reflect/keep out heat-generating wavelengths while allowing visible light through, keeping cabin temperatures lower and protecting interiors.

2. Spectrally-selective TiN nano-ceramic construction

- True sputtered TiN + dielectric multilayer (not dyed or heavy metal particle metallization). Precise layer control lets Orca block IR/near-IR efficiently while keeping visible light transmission and low reflectivity balanced for driving comfort and aesthetics.

3. Optical neutrality & superior clarity

- Very low visible distortion and neutral color — Orca minimizes colored dye layers to preserve true color rendition through the glass; measured clarity targets (0.75–0.90 visual index) provide a near-clear view that enhances driver comfort and customer perception of quality.

4. Signal-friendly, installer-friendly design

- Non-metallic / low RF interference — The nano-sputtered TiN construction can be engineered to be communication-friendly (mobile, GPS, 5G), removing a common objection to older metalized films. The PET substrate plus hardcoat enables smooth cutting, edge seaming, and lower on-glass friction during wet installs.

5. Durability & long-term stability

- Dense, corrosion-resistant TiN layer + hardcoat delivers improved resistance to oxidation, yellowing and surface marring compared with dyed films or coarse metalized films.

6. Premium channel positioning & packaging

- Dealer-ready presentation — Custom PROKHAR packaging, warranty options, and high-end point-of-sale materials position Orca for boutique installers, national chains, and premium fleets that sell performance and assurance, not just price.

7. Performance tradeoffs framed as features

- High heat rejection with balanced VLT — Market the Orca Series as engineered for drivers who want maximum thermal comfort without the “darklook” compromise; offer multiple VLT SKUs while keeping the same TiN architecture to simplify inventory and installation training.

TECHNICAL SPECIFICATIONS

PROKHAR TiN Magnetron Sputtered Car Tint(1.52*30m) Luxury Tier – Orca Series | |||||||

|---|---|---|---|---|---|---|---|

| Model | OC-05 | OC-15 | OC-25 | OC-35 | OC-45 | OC-50 | OC-60 |

| Total Thickness | 2MIL ± 0.2 | ||||||

| VLT Options (%) | 05 | 15 | 25 | 35 | 45 | 50 | 60 |

| UVR | ≥ 99% | ≥ 99% | ≥ 99% | ≥ 99% | ≥ 99% | ≥ 99% | ≥ 99% |

| IRR | 98% – 99% | 98% – 99% | 98% – 99% | 98% – 99% | 98% – 99% | 98% – 99% | 98% – 99% |

| Total Solar Energy Rejection (TSER) (%) | 95 | 90 | 85 | 79 | 74 | 71 | 68 |

| Haze (Without Release Film) (%) | 0.86 | 0.91 | 0.87 | 0.87 | 0.72 | 0.74 | 0.75 |

| Baking Film Shrinkage Characteristics | Four-sided Shrinkage Ratio | ||||||

| Warranty (years) | 5 | ||||||

Ultra-High Heat Rejection & Efficiency

99%+ UV Defense & Interior Preservation

TiN Precision & Nano-Ceramic Clarity

Magnetron Sputter & Spectral Styling

Safety & Anti-Shatter Protection

Seamless Connectivity & Day-Night Visibility

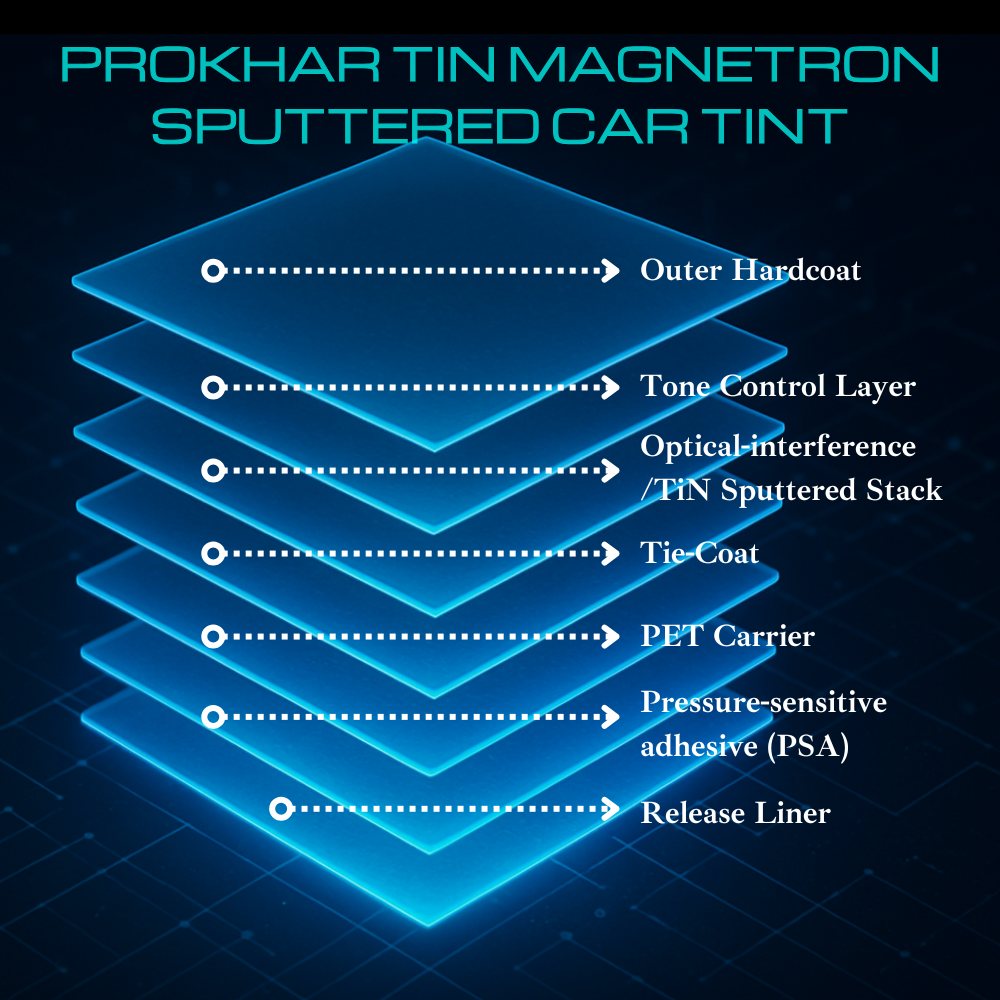

Product Structure

PROKHAR TiN Magnetron Sputtered Car Window Film

A. Outer hardcoat (scratch & weather resistant)

A cured hardcoat is applied to the exposed surface to resist scratches, chemicals and environmental wear. This preserves optical stability during cleaning and installation and reduces on-car abrasion. Hardcoats are typically roll-coated and cured in-line during manufacture.

B. Tone control layer

A very light tone or neutralizing layer adjusts perceived tint and ensures optical neutrality. For PROKHAR TiN lines we minimise dye content (keeps colour bias low) and rely on TiN/dielectric design to control visual appearance rather than heavy pigments.

C. Optical-interference / nano-ceramic + TiN sputtered stack

This is the functional heart of the film: alternating ultrathin TiN layers and dielectric (high/low refractive index) films are deposited by magnetron sputtering to form an optical interference stack. By precisely controlling layer thicknesses and spacing the stack:

- reflects/blocks IR and near-IR (reducing heat load),

- transmits visible light with low reflection and minimal colour shift, and

- maintains low haze / high clarity.

TiN provides the spectral functionality (absorption/reflection and plasmonic behaviour) while dielectric layers tune phase and protect the metal layers. This multi-layer approach is how PROKHAR achieve high IRR with lighter VLTs.

D. Tie-coat

A thin tie layer improves adhesion between the sputtered/coated stack and the PET carrier (or the downstream adhesive). This layer reduces delamination risk and increases long-term durability in automotive environments.

E. PET carrier

An optical-grade polyester (PET) film provides dimensional stability, the physical substrate for coatings and the primary optical base. For PROKHAR premium TiN films we balance handling, cut-ability and optical flatness (factory roll format).

F. Pressure-sensitive adhesive (PSA)

A transparent, UV-stable adhesive bonds the film to glass. The PSA is formulated to avoid yellowing, provide secure long-term adhesion, and allow eventual removal without residue when required.

G. Release liner

A protective release liner keeps the film clean in roll form and is stripped at the installer’s bench just prior to application.

Tint that sells — priced to move.

Distributors get protected pricing and OEM options — request a tailored partner quote for your region.