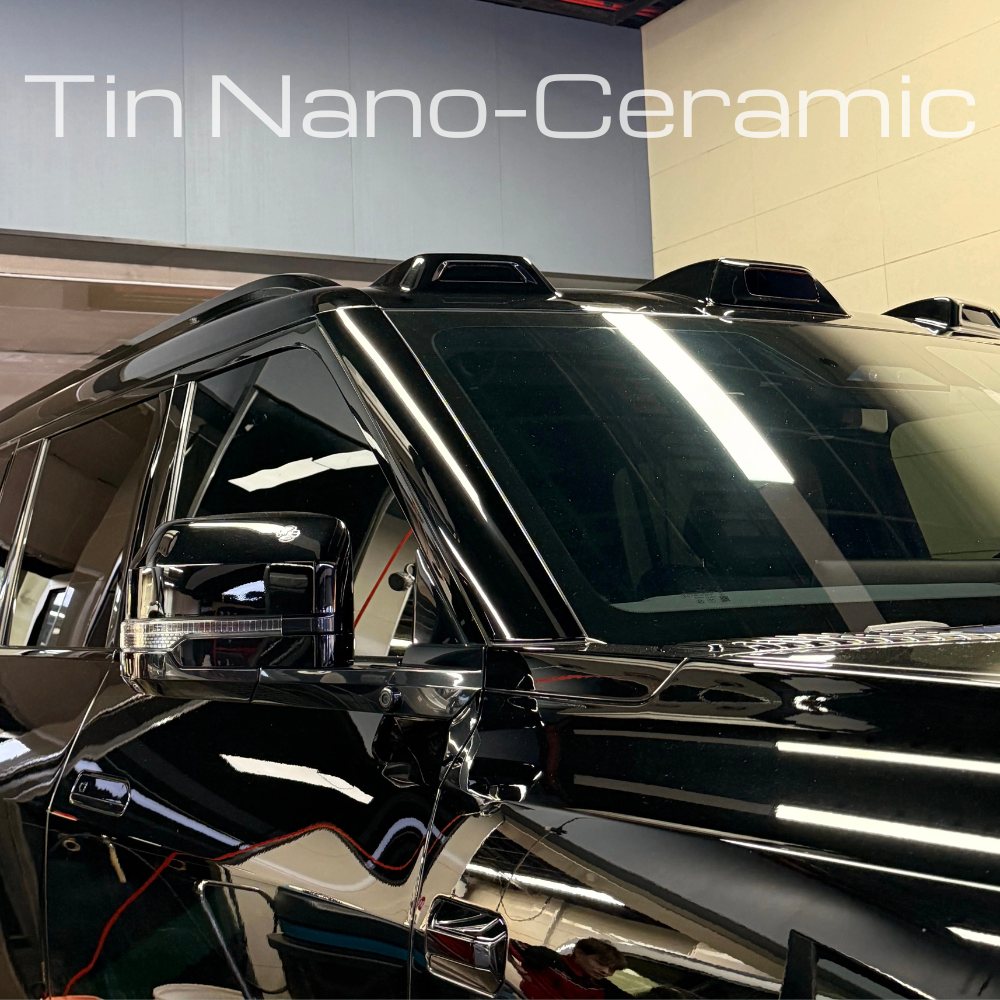

TiN Nano Ceramic

Premium Tier

PROKHAR Tint — Drive Cool, Stay Secure

The PROKHAR Premium family (Humpback, Narwhal, Minke) is a line of 2-mil titanium-nitride (TiN) nano-ceramic car window films engineered for high clarity, stable heat rejection and installer-friendly performance. Each series is manufactured on optical-grade PET and finished with a durable hardcoat and proven adhesive system to ensure long term color stability, scratch resistance and easy on-glass handling. These films are spectrally tuned to reject infrared and UV while maintaining excellent visible light transmission and low reflectivity—designed for busy installers, high-traffic dealers and shops that sell performance and reliability, not just price.

- Humpback Series — UVR 99%, IRR 99%, extreme clarity index 0.1–0.7. Top choice where optical neutrality and daytime/nighttime visibility are paramount.

- Narwhal Series — UVR 99%, IRR 95%, clarity index 0.1–0.6. Balanced performer: very high UV protection and excellent IR control with ultra-clear sightlines.

- Minke Series — UVR 99%, IRR 92%, clarity index <1. Value-oriented Premium SKU that preserves the TiN nano-ceramic advantages while offering broader VLT options for mainstream installs.

KEY FEATURES & ADVANTAGES

- Spectrally-selective TiN nano-ceramic construction — Precision TiN/dielectric stacks deliver strong IR/near-IR rejection with minimal visible light reflection, keeping cabins cooler without “dark” or colored visual tint.

- Industry-level UV protection (≥99% UVR) — Protects interiors and occupants from UV-driven fading and skin risk.

- Ultra-high clarity — near-zero haze — Clarity indices in the Humpback/Narwhal range (0.1–0.7) position these films as premium optical solutions: ideal for drivers and fleets that require excellent day/night visibility and minimal color shift.

- Signal-friendly installation — Engineered to avoid the RF/communication problems associated with heavy metal films; supports mobile, GPS and modern in-car connectivity so customers keep full device function after tinting.

- Durability: corrosion & fade resistance — Dense TiN layers plus a hardcoat resist oxidation, yellowing and surface marring better than dyed or coarse-metal films.

- Installer ergonomics & consistent inventory — Standard 2-mil construction across the Premium family simplifies cutting, training and stock management for larger shops and chains; multiple VLT SKUs can be offered while keeping the same core chemistry and warranty terms.

- Clear channel message for dealers — “Premium clarity, proven solar control, zero signal tradeoffs”

TECHNICAL SPECIFICATIONS

PROKHAR TiN Nano-Ceramic Car Tint(1.52*30m) Premium Tier | |||

|---|---|---|---|

| Series | Humpback Series (HB) | Narwhal Series (NW) | Minke Series (MK) |

| Model | HB – 05 / 18 / 25 / 30 / 50 / 70 / 75 | NW – 05 / 15 / 35 / 50 / 70 / 75 | MK – 05 / 15 / 25 / 35 / 50 / 75 / 78 |

| Total Thickness | 2MIL ± 0.2 | 2MIL ± 0.2 | 2MIL ± 0.2 |

| VLT Options (%) | 05 / 18 / 25 / 30 / 50 / 70 / 75 | 05 / 15 / 35 / 50 / 70 / 75 | 05 / 15 / 25 / 35 / 50 / 75 / 78 |

| UVR | ≥ 99 % | ≥ 99 % | ≥ 99 % |

| IRR | 98% – 99% | 95% | 90% – 92% |

| Total Solar Energy Rejection (TSER) (%) | 94 / 89 / 84 / 78 / 72 / 70 / 67 | 93 / 86 / 80 / 70 / 56 / 59 | 90 / 85 / 80 / 75 / 70 / 53 / 58 |

| Haze (Without Release Film) (%) | 0.62 / 0.68 / 0.36 / 0.60 / 0.45 / 0.18 / 0.50 | 0.58 / 0.36 / 0.37 / 0.47 / 0.18 / 0.28 | 0.72 / 0.69 / 0.93 / 0.60 / 0.98 / 0.17 / 0.40 |

| Baking Film Shrinkage Characteristics | Four-sided Shrinkage Ratio | Four-sided Shrinkage Ratio | Four-sided Shrinkage Ratio |

| Warranty (Year) | 6 | 5 | 5 |

Ultra-High Heat Rejection & Efficiency

99%+ UV Defense & Interior Preservation

TiN Precision & Nano-Ceramic Clarity

Magnetron Sputter & Spectral Styling

Safety & Anti-Shatter Protection

Seamless Connectivity & Day-Night Visibility

Product Structure

PROKHAR TiN Nano-Ceramic Car Window Film

A. Outer hardcoat (scratch & weather barrier)

A UV/thermally cured hardcoat protects the functional stack from abrasion, chemicals and weathering. It preserves surface gloss and prevents mechanical or environmental damage to the underlying sputtered/ceramic layers during handling and installation.

B. Optical overcoat

A transparent tuning layer that mutes metallic glare, controls visible reflection and refines the film’s perceived tone. It also acts as an interface between the hardcoat and the optical stack to maintain optical neutrality and consistent aesthetics.

C. Nano-ceramic functional layer

A dispersion of non-metallic nano-ceramic particles that increases IR absorption/scattering, improves thermal stability and reduces the metal layer’s sensitivity to oxidation. By adding targeted ceramic functionality the film raises overall TSER while enabling non-metallic signal-friendly options—core to PROKHAR’s high-end nano-ceramic strategy.

D. Dielectric optical stacks (multi-layer interference layers)

Alternating high/low refractive index dielectric layers tune phase relationships in the stack so the film selectively reflects NIR/short-wave IR while transmitting visible light with minimal colour shift. These interference layers enable precise spectral shaping (visible vs NIR) and are critical to achieving high IRR with low VLT impact.

E. TiN magnetron-sputtered functional layers

Ultra-thin TiN sputtered layers provide metallic-like selective reflection in the NIR while remaining relatively transparent in the visible band. When alternated with dielectrics, TiN enables strong NIR rejection, refined spectral curves and controlled colour bias—delivering the “spectral selectivity” that separates premium PROKHAR TiN films from dyed or bulk-metalized products.

F. Sealing dielectric layer

A dense oxide/nitride barrier prevents moisture and oxygen ingress to the metal/ceramic stack, improving corrosion resistance and long-term durability—particularly important for sputtered metal layers exposed to humid or coastal environments.

G. PET carrier

Optical-grade PET provides dimensional stability, handling strength and a flat optical substrate for sputtering and coating. PET thickness is selected to balance cut-ability, shrink behaviour and on-vehicle conformability.

H. Pressure-sensitive adhesive (PSA)

A transparent, UV-stable PSA bonds the film to glass. Formulated to resist yellowing, maintain peelable removability and ensure long-term adhesion without leaving residue.

I. Release liner

Protective liner keeps rolls clean and non-sticky during storage and shipping; it is peeled away immediately before installation.

Tint that sells — priced to move.

Distributors get protected pricing and OEM options — request a tailored partner quote for your region.